MORE INFORMATION

SPECIAL ATTENTION

When you cover a pool that’s more complex than the average rectangle, certain features present their own challenges.

- Islands

- Planters

- Caves

- Vanishing edges

- Paver decks and lawn

- Wood decks

- Glass or glazed surfaces

- Artificial rock

- Rock waterfalls

- Dive rocks

For islands, columns or anything else protruding higher than deck level, you’ll need to order the cover with a boot cut. This is a hole that accommodates the feature. A slit runs from the boot cut to the edge of the cover, and installers will close this incision with D rings or clips after the cover is in place. The cover is attached to the island using a cable assembly or special hardware provided by the manufacturer.

When measuring the cover, you’ll need to plot out points all around the island, which may require additional stakes. It’s a good idea to measure from at least two sides of the feature.

When a planter sits directly adjacent to the pool, use extension straps. They stretch up to 8 feet and are adjustable. Simply weave them through the foliage, and anchor them into the deck on the other side.

When the pool is closed, caves must be shut off as well. One method of doing this is to run the cover inside the cave and attach it with a cable assembly. Another option is pulling the cover over the cave opening and anchoring it onto the outside surface. This requires installing a cable to hold the bottom part of the cover and an anchoring system above it.

These edges can be handled with a version of either the up-and-over method or cable assembly. For up-and-over, drape the cover over the vanishing-edge weir wall, and use it to envelop the catch basin entirely. The cable assembly allows you to hook the cover directly to the back of the vanishing-edge wall. The advantage here is a cleaner, more attractive look. But this system also leaves the catch basin uncovered. Be sure to explain this to the customer.

Measuring for this feature will be different. For the rest of the aquascape, you supply the pool measurements. Then the producer knows how much overlap to add to the cover so that it sits securely on the deck. Because vanishing edges are so unique, you must decide how much overlap you need around it, and tell the manufacturer what size to make the section of cover that goes over the vanishing edge.

On its own, a regular deck anchor can’t grab into soil or the soft sand bed underneath pavers. Instead, you’ll need to install aluminum tubes into the ground. This product, provided by the manufacturer, goes directly in the lawn or between the pavers. A standard anchor then sinks into the tube and sits flush with its top.

The tubes measure 7/8 inches in diameter, but Frank Christiana likes to use a 1-inch drill bit when creating a hole for them. “With a 7/8-inch hole, if there was just a little piece of stone sticking out, the tube would not go into it,” says the owner of Safety Cover Specialists and Liner Specialists in Holmes, N.Y. “So we make it slightly larger to give us enough wiggle room to get the tube down without cutting it and compromising the integrity.”

Aluminum tubes go down 18 inches, which may not be deep enough for sand or loose soils. In that case, take a 3-foot-long piece of rebar, pound it into the ground and slide the tube over it, Balbo says.

Because wood decks are generally only 2- to 3 inches deep, these surfaces need a special anchor. Called a wood deck anchor, it has a flange around the top, with four to six screws to hold it in place. You’ll need two to three drill bits — at least one for the main body of the anchor, then another for the screws.

When ordering the cover, be sure to let your supplier know the deck is wood. If the project is a combination of wood and another material such as concrete, indicate where the wood begins so the vendor knows what kinds of hardware to provide.

To prevent damage, don’t use a regular rotary hammer to drill into decking material that has a hard glaze on top. Instead, stick with a rotary masonry bit. If you have to drill into glass tile for the cable assembly, use a glass-cutter drill so the material doesn’t shatter.

Some artificial rock is hollow, which will prevent an anchor from being properly secured. If the feature is short enough, use the up-and-over method and anchor it to the deck.

If you need a cable assembly, there are two options for setting the eye bolts or eyelets. The first is to find a place below the rock to install them. “Instead of going into the vertical rock wall, we go down into the deck so the eyelet stands up instead of jutting out toward the cover,” Christiana says. The other choice is to set the anchors in the rock using an epoxy.

Choosing how to place the cover around a stack of rocks is highly subjective. Be sure to consult with the homeowner. “Sometimes you have to make a choice and ask the homeowner, ‘Would you like the cover to be tucked under that large stone, or would you like it over that?” Christiana says. They may want to leave as much of the rock exposed so they can still enjoy it during winter.

You may decide to tuck the cover underneath a dive rock. If so, be sure to order padding and place it between the rock and the cover. That way, when the cover flaps in the wind, it won’t become worn from the surface of the rock.

Considering the intricacy of some pools built in the last decade, measuring and installing a safety cover can become a much more complex procedure than in the past.

Frank Christiana knows this firsthand. He sometimes goes to extreme lengths to measure around, say, the front of a large rock waterfall.

“I have pictures of me hanging upside down on a waterfall, literally heels over head to measure a pool,” says Christiana, owner of Safety Cover Specialists and Liner Specialists in Holmes, N.Y. “I also have photos of myself in a kayak, because sometimes you can’t even hang over the waterfall, they’re just so large.”

Experts agree that projects containing raised walls, waterfeatures, caves or anything else that stands above deck level can be tricky. A number of methods must be used to measure and secure the cover.

Measuring the cover

When dealing with the obstacles inherent in a complicated pool, you can’t just set up two stakes and use the simple A-B triangulation method.

For one, you may need more chalk marks around the vessel than normal. Any time the pool’s outline changes direction — whether for a beach entry, waterfall or other feature — you’ll need one mark on either side of the element, then at least one more in the middle, says Brian Balbo, vice president of sales and marketing at Gorlin Pools and Spas in Lakehurst, N.J. This last mark is skipped by many installers, he adds, but it’s crucial to show how far into the pool the item protrudes so the area can be padded properly and the cover attachment can be determined.

For larger, complex or unusually shaped features, even more points may be necessary. When in doubt, add more. Too many markings will never pose a problem, but too few can force the cover manufacturer to guess the exact dimensions. This can result in a cover that doesn’t fit.

Measuring complicated pools may also require more stakes. As usual, each mark around the pool must be measured from two places. But when a pool is surrounded by rockwork, planters and the like, professionals must measure in such a way that the raised elements don’t get in the way.

“If you use a tape measure and just go up and over a rock or around a rock, you won’t get an accurate measurement of that distance,” Balbo says.

You may have to add more stakes in order to run the measuring tape cleanly to every point. “Some pools require an A, B, C, D and E [for] measurements for the backsides of bars, rock formations, slides and waterfalls,” Balbo says.

In these cases, you don’t need to measure from every stationary point to every chalk mark. Each chalk mark should be measured from two stakes. “So if you look at the points on a piece of paper, normally you just have a column for A and a column for B,” Balbo says. “Now you’re creating columns C, D and E, if that’s what it takes. But column C may only have four points on it; and column D may only have eight.”

When measuring, remember that the cover won’t just hug the pool perimeter. Instead, the fabric will overlap onto the deck by 12- to 18 inches. Provide measurements for anything within that space.

With the measurements complete, you must accurately communicate them to the manufacturer. Take the extra time to fill out a printed form, and provide photos from all angles. This helps verify that you haven’t left anything out.

“Go out and buy a $100 camera,” Christiana advises. “If you mess up one $1,500 cover, you’ll say, ‘I wish I had 15 cameras!’”

Finally, dealing with an elevated spa can trip up a lot of builders. Though it’s tempting to only measure to the outside of the raised wall, don’t be fooled. Run the measuring tape to the inside of the spa, where the water meets the concrete. Be sure to indicate the location of all spillways because the manufacturer probably will want to include padding on that section to help protect the cover from the sharp edge created by the weir.

Attaching the cover

When ordering a cover, you must decide how to attach it to any raised features that sit on or near the pool wall. A safety cover has to be completely secure, but you can’t rely on straps to do the job. Without coping and deck to which they can adhere, you must use a different option. Here are two methods that work in these situations.

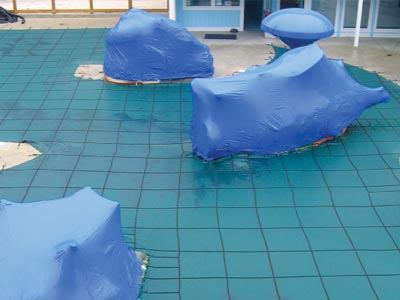

Up and over: Here, the cover is extended over the obstacle; regular anchors and straps are attached behind.

While this is the simplest, least expensive solution, there are also drawbacks to consider. When installed over a higher surface, the cover forms a sort of ramp, allowing dirt, water, debris, snow and ice to slide down and congregate at the bottom. The extra weight puts stress on the cover at the spot where it’s attached to the feature, causing it to wear prematurely even with padding.

For this reason, cover manufacturers put limits on up-and-over installations. Some will go as high as 2 feet, if done in increments; others cap it at 18 inches.

Bob Huss won’t elevate a cover more than 12 inches. “We have a lot of wind in our area and, if you make the cover too high, debris can blow underneath,” says the owner of Pool Care Specialists in Chadds Ford, Pa. “No matter what you do, you can’t keep the cover tight enough to stop debris from blowing under.”

Without the right precautions, an up-and-over cover can wear out in a single season. It doesn’t lay flat on the deck, so it will rub against the raised corners and surfaces. If you choose this type of installation, use the highest-grade material available, and order padding for those spots where it will rub.

Dave Bachman, manager of Don Marcum’s Pool Care in Newtown, Ohio, tells his clients to order remnants of carpet. When closing the pool, they can lay the carpet over raised features, plush side up.

Another problem with elevating the cover is the gaps that are created along the sides of the feature. This makes it possible for children and pets to get inside. It’s important to close these spaces with a step-riser kit, wedging triangular-shaped pillows into the open gaps.

“They have little tabs on them to drill the anchors into the deck to hold the pillow into place,” Christiana explains. The pillows are filled with pieces of cover scrap that can be added or removed to help fit the space tightly.

Cable assembly: For this system, the cover is clipped to a cable that wraps around the feature. Raised spas or waterfeature basins receive a separate cover.

To do a cable assembly, first install a series of lag shields along the pool wall using a special tamping tool. The shields work like a Molly screw in a house wall — several “claws” spread out and firmly grip the wall.

Eye bolts or eyelets (depending on the manufacturer) then are placed inside the lag shields. Some can be removed when it’s time to open the pool, while others remain in the wall. When positioning these components, look for grout joints, darker spots or other areas where the hardware will be less conspicuous. This is especially important when the pieces are going to stay put during swim season.

A stainless steel aircraft cable measuring about a quarter-inch thick then goes through the eyelets or eye bolts. The cable will be removed each spring when the pool is opened. The cover attaches to the cable using clips that the manufacturer sews into the fabric.

Unlike the up-and-over method, this entire assembly is placed at deck level so the cover does not envelop the raised features. Instead, it attaches along the front of them and extends one foot on either side.

“Usually, if there is a 10-foot waterfall, you’ll have a 12-foot length of cable,” Christiana says. “You’ll have a 1-foot overlap, so it’s basically like wrapping a string around your belly, where you anchor it by the back of your hips.”

While many professionals like cable systems, some prefer a modification called the direct hookup. This involves setting the same hardware into the waterfeature. But rather than running a cable, you attach the cover clips directly onto the individual eye hooks or eyelets. Some believe that the cover fits more tightly because if it were on a cable, it might sway.

But others think this method doesn’t hold up. When snow, water and winds place extra weight on the cover, the additional tugging can pull the hardware out of the wall over time, Balbo says.

The modified system also requires more eye bolts — one for each cover clip. And you can’t always choose where to place the anchors. On stacked rock, for instance, they must be installed in grout joints, or in parts of the stone that are strong enough to hold the hardware and soft enough to allow drilling. This makes it more difficult to line up the eye bolts so that the straps stay straight. “If your anchoring point is off a little bit, the strap lines start getting crooked, and it can throw off the 3-foot grid on top of the cover,” says Paul Wahler, general manager of Poolservice Co. in Arlington, Va.

The cable assembly method and its direct hookup sibling can be expensive. The extra hardware and exacting measurements mean the cover costs more to produce, and installation takes still more time and tools. Even yearly openings and closings of the pool become pricier.

“In the amount of time it takes you to do one anchor, you could do half the pool with a normal deck installation,” Balbo says.