The pool service business uses specialized tools from custom wrenches to unique plumbing parts. It’s also an industry full of creative, innovative people.

Combine the two and you get techs across the country developing their own, distinctive tools and processes for dealing with the issues they face every day.

Some are tools originally designed for other industries, adapted for use in pools and spas. Others are entirely novel concepts, created out of sheer necessity.

Here, pool service veterans share the stories behind some of their most inventive and helpful discoveries.

Water inducer

Daniel Spatz

Owner, Bullseye Leak Detection

Sacramento, Calif.

Source: plumbing supply shop

When my service guys are out doing their routes, they’ll encounter debris — leaves and things like that — obstructing the suction line. It’s especially a problem in winter, when a lot of homeowners keep their pumps turned off.

Some guys carry around a blow-out kit, which is a pressurized air tank with a hose that you hook up to the suction line. It uses high-pressure air to blow out the blockage. But those can get expensive, so I was looking for a simpler solution that all my guys could carry with them.

What I found is called a water inducer. It’s what a plumber would normally use for a plugged-up 1½-inch or 2-inch pipe. It’s basically just a metal pipe. We attach a hose adapter to one end, and run a hose to the inducer from the homeowner’s spigot. We tighten the inducer down on the pipe, and then use water pressure to force debris out of the line.

Spa sled mover

Steve Weisbrod

Owner, Spa Place

Nixa, Mo.

Source: custom-built

My crew and I install a lot of spas. It was always kind of a pain to move them around a yard. We’d roll them on top of PVC plumbing, or slide them across a piece of carpet or a piece of cardboard — anything we could use to reduce the friction with the ground. And even then, we’d still end up scratching the spa a lot of times.

A few years ago, I found out about the little “movers” you slip under the legs of heavy pieces of furniture, to make them easy to slide across the floor. I always kept those in my truck, and would use them for various jobs where I needed to move something heavy.

Then one day I got the idea to combine the concept of the movers with the piece of carpet or cardboard. I called the company, and asked if they’d build me a single mover that was big enough for a spa to slide across. At first, I didn’t get any response. But I stayed persistent, and eventually they called me back and said they thought that was a pretty good idea. So they built me one.

I call it the spa sled. It allows one or two people to move spas or any other heavy bulky items that would otherwise require several people. I’ve sold a few to other service guys through my Website, www.spa-mover.com. And in my own day-to-day work, I never leave home without it.

5-in-1 painter’s tool

Hillel Salomon

Owner, American Leak Detection Berkeley, Calif

Source: art supply shop

We work with a lot of press-in pool return fittings. The way most of us over the years have pulled those off is to grab on with a pair of pliers and kind of wiggle them. It works, but the teeth of the pliers leave marks all over the fittings.

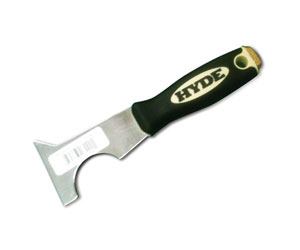

I found something called a 5-in-1 painter’s tool that does the same job without the damage. It looks kind of like a putty knife, only with a curved edge. A painter uses it for scraping and spreading paint, but it’s also a really good tool for removing press-in jets.

Because the 5-in-1 tool has that curved edge, it’s the ideal shape to slip behind the fitting and leave you some wiggle room. We just slip it behind the fitting, like a putty knife, and wiggle it to pop the fitting off. It only takes a few seconds, and it doesn’t leave a single mark.

Fold-up cart

Lance Sada

Owner, A Clear Choice Pool Service

Menifee, Calif.

Source: home improvement store

A lot of guys keep work dollies in their service trucks, but I just have a pickup, so I try to be very space-conscious.

About a year ago, I ran across a hand cart at the home improvement store. When you fold up the piece that holds the weight, it tucks the wheels in, and then the handle collapses on itself. It’s about 18 inches wide by a couple feet tall when it’s unfolded. And it folds up so small, I can stick it behind the front seat of my truck.

It’s handy for chlorine drums or hauling motors and miscellaneous parts. You can stack them up and wheel them around. The cart does have a weight limit — about 150 pounds — but that’s plenty for moving something like a smaller heater.

It’s all aluminum and plastic, so it’s lightweight, but it’s really durable. Mine’s looking a little rough, but it’s holding up fine. My cart helped me out so much that I had to spread the word, so I know a few other service guys have started using them too.

PVC auto-fill and manifold

Lance Sada

Owner, A Clear Choice Pool Service Menifee, Calif.

Source: custom-built

When we’re filling a pool at a site where there’s no one around to watch it, we need a way of automatically shutting off the flow of water when it reaches a certain level.

We’d usually put in auto-fills that fit inside the skimmer basket. But I used them on so many projects, I figured there had to be a simpler way to build auto-fills myself. So I took some PVC pipe, and found a fitting at the hardware store that would adapt to a hose tip. Then I screwed that into a fitting I got from the plumbing store, and I glued it into the PVC, and attached a plastic float valve that I got from a pool supply store to it. When the water rises to a certain level, it closes the valve and shuts off the flow.

The problem was, that valve only permitted a flow rate of 1.5 gallons per minute. I figured, 1.5 gallons times 60 minutes times 24 hours — it’d take a week to fill up a pool. So I thought, “All I need to do is figure out how much water flows through a wide-open hose in a minute, and attach enough of my auto-fills together to equal that flow rate.” I took a rough estimate by running some water from the hose into a bucket, and figured I’d need six of my auto-fills to equal the flow rate of a hose.

So I adapted my idea into a six-unit manifold. Instead of just one float, I attached six together in a “T” shape, with the hose attaching to the bottom of the “T.” That has the same flow rate that a wide-open hose does. Now, when we have to drain a pool and refill it, we’ll hook the six-unit manifold up to it, and the pool will refill in roughly 24 hours.

• Ultimate Tech Manual: Useful Tools

Turn to these indispensable tools when on your route.

• Ultimate Tech Manual: Tool Organization

Tips for properly storing the gear on your truck.