Phoenix-area builder Red Rock Pools & Spas is working on one of its biggest, most complex backyard projects to date, incorporating features rarely used in residential applications, along with massive scale and intricate engineering. In this series, Red Rock Co-owner Rick Chafey introduces it.

This year, we are embarking on one of our most ambitious backyard projects.

Our client purchased two homes, knocked them down and is building one large property with the kind of amenities that you’d normally find in a full-scale resort or waterpark.

Red Rock Pools & Spas

The exterior portion of the go-kart track can be seen in the for…

Everything about it is big. We’ve been working on this design for about 11 months — and we’re continuing to design as we speak. It’s a living thing that will likely keep evolving until it’s finished. So far, we’ve devoted roughly 500 hours on the design and engineering. The structural engineering package on this project, alone, has cost more than $100,000. And we’re continuing to work on this part of the job, as the client has made some last-minute changes.

We expect the project to use about 850 yards of shotcrete — if I’m estimating conservatively. We may approach 1,000 yards by the time we’re done.

The job will keep us busy for about 18 months, probably taking us well into 2022. I’ll be providing periodic updates to discuss the highlights and challenges as it progresses. For now, here’s a tour of the waterscape so far, along with some of the primary challenges we’ll be dealing with.

The high points

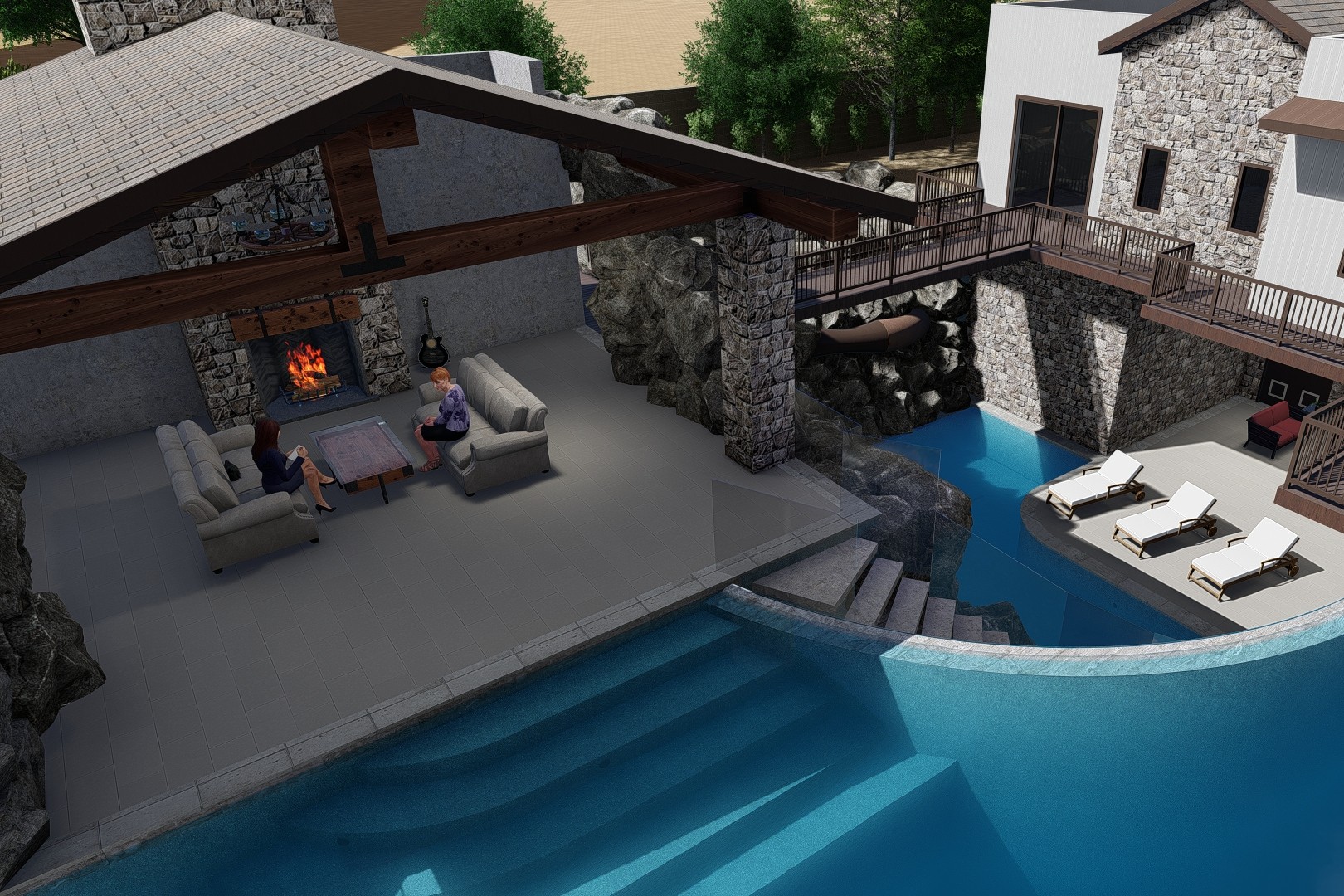

The main pool features a sunken firepit, swim-up bar, planter island, and pavilion. Besides that, the yard has several components that transform the yard into a residential waterpark resort:

° Lazy river with underground go-kart track

The lazy river will run approximately 540 feet throughout the backyard, powered by ten 10-horsepower Riverflow Pumps from Current Systems.

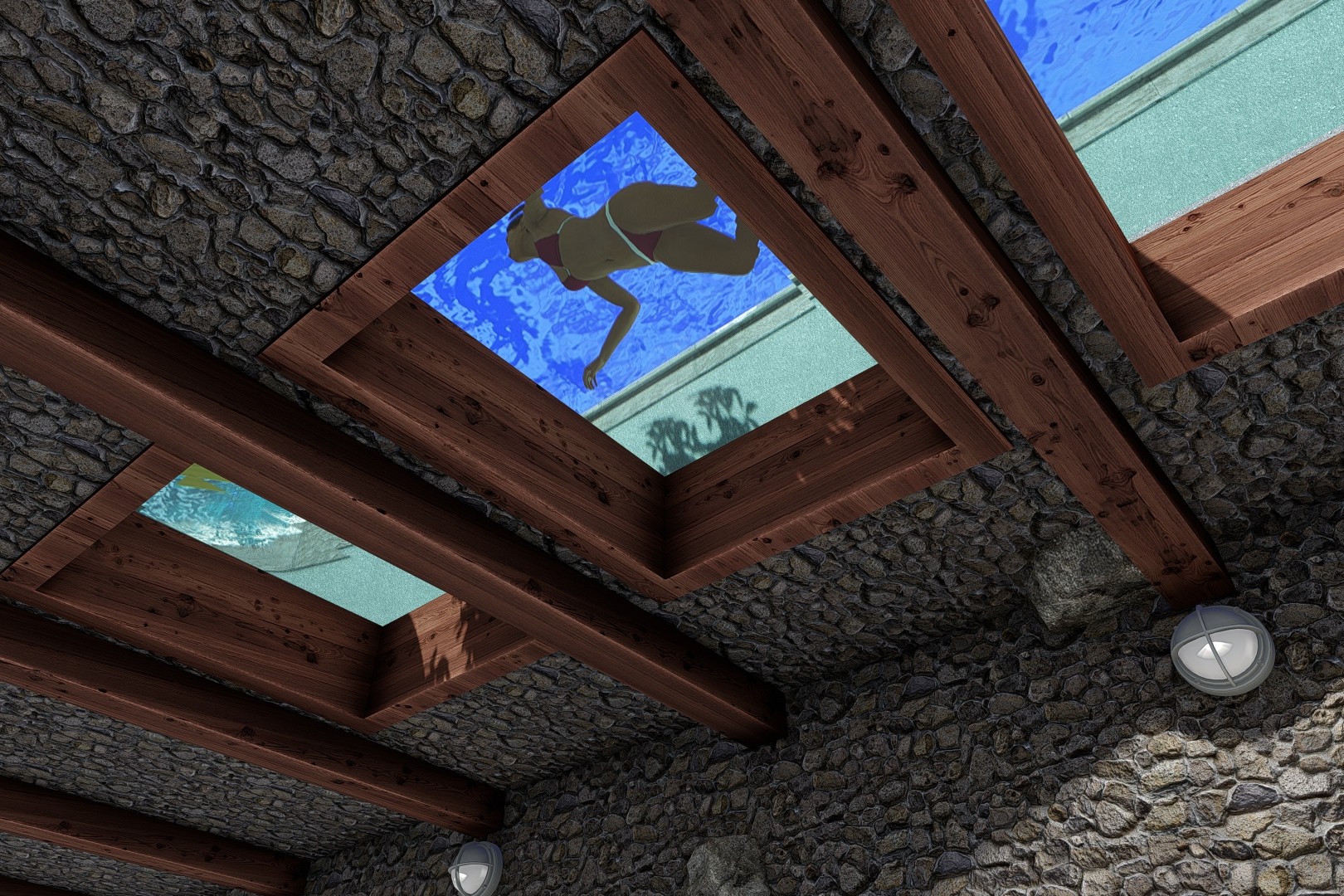

Beneath the lazy river, underground, will run a 494-foot-long go-kart track designed to look like a mine shaft of sorts. It runs at ground level then goes subterranean, following the river from below for about 150 feet before it comes back up. Eight windows in the river floor serve as skylights for the track, allowing go-kart riders to look up into the water.

Despite its scale, the lazy river is one of the easier features to engineer — the construction and engineering are fairly conventional. But we are bearing part of it on top of the tunnel with the go-kart track, which will require the river bottom to span over a set of retaining walls.

° Rock waterfall, grotto and slides

Made with a combination of real and artificial boulders, the rock waterfall will have two slides — an open flume and a tube slide that wraps around the back. The extensive grotto underneath will include a bar and also be themed like a mine shaft, with exposed posts and beams, in addition to the rock work.

We will use mostly natural rock, so the waterfall will require a significant support structure.

° Surf simulator

This is a specialized FlowRider surf simulator that you’d normally find at a waterpark. But this inflatable version deflates when not in use so it can be folded and tucked down, then concealed by a Twinscape motorized movable floor covered in artificial turf. This leaves more usable space while protecting the surf machine from the sun. It also makes the huge blue structure disappear for aesthetic reasons. The manufacturer customized the simulator to work with the movable floor. It’s designed like a stand-up paddle board or rigid inflatable boat — it can roll up but, when inflated, it becomes so rigid it almost feels like fiberglass.

This will require plenty of electrical work and a 125-horsepower pumping system.

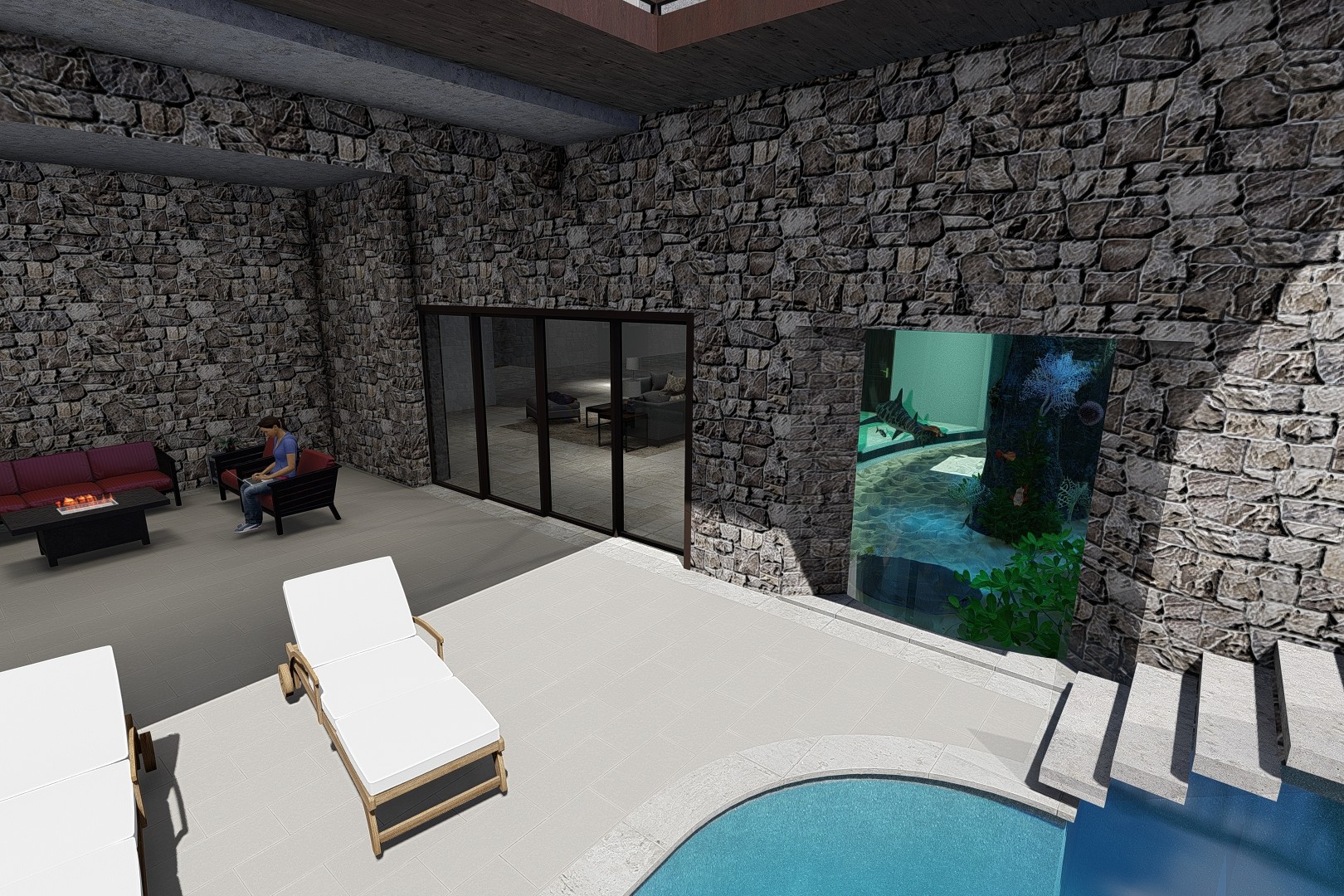

° 30,000-gallon shark tank

This will be placed in a shared wall between the main pool and the living room. Needless to say, this substantially complicates the engineering for the main pool. One of the walls is more than 24 inches thick.

Any acrylic panel construction is already complicated. But here we have an added degree of difficulty: The panel that’s placed in the pool wall will have water pressure on both sides, coming from both the pool and the shark tank. Normally, when you only have water on the pool side, you place the panel in the rebate or slot, and the water pressure from the pool pushes the window up against the rebate and sealant. With water on both sides, we’ll have to create what I call a toaster slot, sliding the window into a rebate in such a way that either the pool or shark tank can be drained without affecting the other body of water.

The shark tank also will support about 10 major loads from the main house. So it’s all a monolithic structure, with some movable places on our connection to the house that allows the elements to shift without breaking another. The shark tank and pool can’t move away from each other at all because they have to hold water. So we’re continuing to work through those little nuances to finalize how this engineering feat is going to work.

° Basement pool

From the pavilion, a set of stairs will lead down to another pool at basement level. A deck accommodates plenty of poolside seating, and this space affords another view of the shark tank. A waterwall spills from the main pool down to the basement pool.

We didn’t want the acrylic panel from the basement into the shark tank to look like just a small window. Instead, it needed to span floor to ceiling, to better immerse the viewer. The overall depth of the basement dictated a 17-foot-deep pool.

This area presents another major engineering challenge. Underneath the basement pool, I have a 25,000-gallon surge tank. The basement starts at 18 feet below grade, and our surge tank goes another 10 feet. That means we’re about 30 feet in the ground. So we had to perform massive shoring using different construction methods that allowed us to dig right next to a neighbor’s property and the basement structure. We didn’t have the space to bench the excavation (dig 5 feet, move over 3 feet, dig down another 5 feet, etc.). Instead, we had to drill and place piers in the ground, then shotcrete between those piers and create a shoring detail that could support the structures above and protect the workers below.

With the basement pool sitting on top of the surge tank, and the main pool on top of the basement pool, there’s a lot of height and structure in that space, which requires substantial engineering and shotcrete. We sometimes need to use larger rebar — up to No. 6 — which can make it harder to use conventional shotcrete methods.

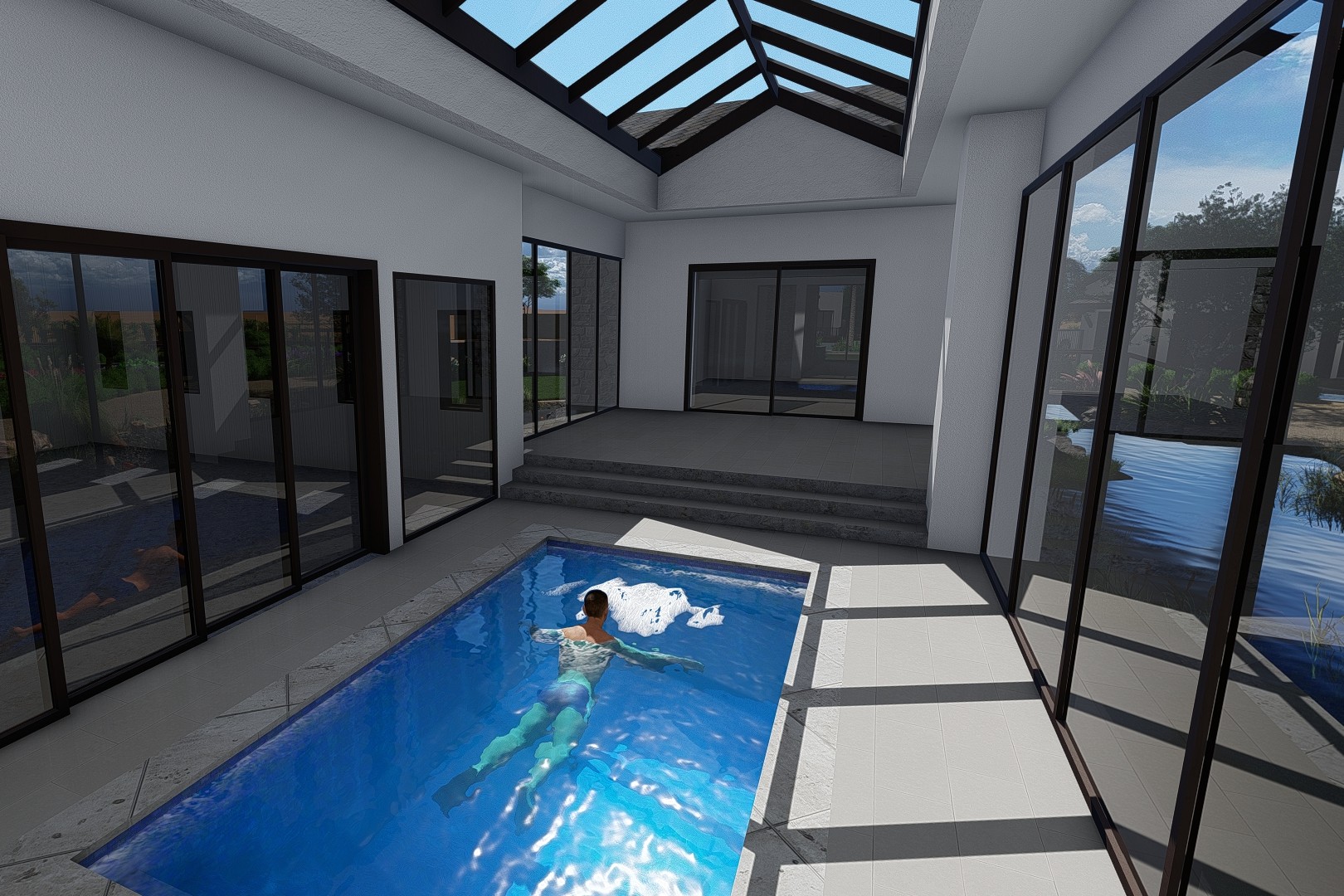

° Indoor pool

Off the master bedroom will be an indoor swim spa with an operable glass roof. A gym goes next to that, with a koi pond wrapped around it.

Things to consider

As you can see, this project has a lot of moving parts. And while it is a large property, the home’s L shape boxed us into place.

Bringing everything together into a cohesive floor plan took an iterative process. We knew we wanted the homeowner to come in the front door and look across the main pool to the pavilion. Then we worked from there, meeting with the clients dozens of times to find out what was critical to them.

We will address some pretty dynamic hydraulics issues — some of which we’re still fine-tuning. For instance, the surf simulator takes water from the pool and river, then deposits it back to the river. We have to manage how that transfer affects the river flow. With ten 10-horsepower pumps in the river and a 125-horsepower pump running the FlowRider, we’re moving copious amounts of water. We’re going through the fluid dynamics to make sure we don’t create major eddies that can stop the river from flowing, or cause overflowing. We’re working with specialized engineers and the manufacturers to analyze this aspect of the design.

Then we will have to determine the surge-tank capacities for these larger bodies of water and develop backup systems so they don’t flood the entire basement.

Outlook

The major components will be built in three phases. The shark tank will be built during Phase 1, since it’s cast-in-place concrete and provides support to a significant portion of the home and waterscape. The main pool makes up Phase 2, then the lazy river and surf machine will be built during Phase 3.

At this point, we’ve started placing the surge tank that goes under the basement pool. We’re taking a short break now: Typical of these projects, we had to chop some of the basement walls and foundations apart, after the client decided to add the shark tank back in. That’s going to change the locations of pump rooms and other things, so we expect to be back under construction shortly after we figure those things out.

Of course, part of the timing will depend on perhaps the biggest challenge of all — finding available subcontractors during one of the busiest times in the industry’s history. For instance, the company that normally does our shotcrete would have to spend weeks on the job, with all their key crews in play. So it’s going to be tough to keep everybody engaged, knowing there’s other work to do.

I’ll keep you posted.