The Department of Energy’s new “Energy Conservation Standards for Dedicated-Purpose Pool Pumps” takes effect July 19.

This means that July 18 will be the last day to manufacture pumps that do not meet the DOE’s efficiency standards. While manufacturers have had to do the heavy lifting since the rule passed four years ago, builders, service professionals and retailers will need to develop their own plans and familiarize themselves with new terminology and potential ripple effects of the new rule.

Here, we offer a mix of updates, advice and explanations of the new measurements that will be implemented.

⦁ About the efficiency rating

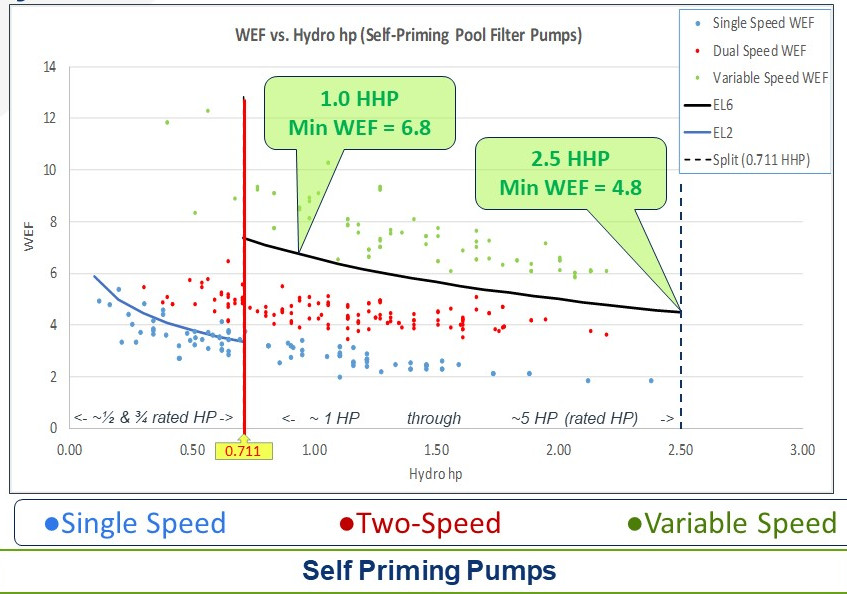

Compliance with the pump rule will be based on one metric — weighted energy factor, which combines motor speed and efficiency with the hydraulic efficiency of the wet end. The term often is shorthanded to WEF (pronounced weff) and is measured in thousands of gallons per kilowatt hour. So a WEF of 12 means it generates 12,000 gallons per kilowatt hour.

To comply with DOE, a pump must meet a minimum WEF. Each pump’s required WEF is based on its size.

Not only does this measurement determine compliance, but it also provides a means of comparing pump efficiency. Derived from the electrical efficiency of the motor and hydraulic efficiency of the wet end, a pump’s WEF will be printed on the product label. The higher the rating, the more efficient the pump. The scale is linear, so a WEF of 10 indicates the pump is twice as efficient as a model that scores a five.

“We’ve had very efficient pumps in the market for a while now, but this will make the comparison and explanation easier to understand,” says Scott Petty, senior global product manager of pumps for Hayward Pool Products in Berkeley Heights, N.J.

This rating shouldn’t be the only thing to consider when choosing a pump. First, start with the job the pump must do — gallons per minute it must generate, the feet of head it must overcome.

“If you’re an off-roader, you’re not going to take a Toyota Prius on dirt trails,” says Steve Jones, senior product manager of pumps for Fluidra, whose U.S. headquarters are located in Carlsbad, Calif. “You’re going to want a Jeep Gladiator — it does not get as good gas mileage, but it’s the right car for the job. I would say the same thing for pumps: You need to get the right pump first, then you can worry about WEF.”

⦁ A new approach to horsepower

It seems the new rule will put to rest a long-held industry tradition that many found annoying and confusing.

When the federal government discovered how pool and spa pumps historically have been rated for horsepower — with total horsepower and uprated or max-rated horsepower — officials said that wouldn’t work. Believing the practice was too confusing, they required that pumps be labeled with the Total Horsepower.

“When they did their research, they found out that not only homeowners were confused but even pool professionals were confused — ‘Do I have a 2.5 hp motor or a 2hp motor?’” Jones explains.

Some believe this could complicate the process of finding new, compliant pumps to replace those that no longer can be produced. Even replacing like-for-like can become confusing, as pumps likely will show different horsepower ratings than before.

“The intent for this new horsepower labeling system was to eliminate some of the confusion created by the dual rating system previously used in the industry,” Farlow says.

As a general rule of thumb, Jones says, subtract ½ hp from the max rating to arrive at the approximate Total Horsepower you’ll need. If an older pump needing replacement was labeled at 2½ horsepower, a comparable unit may be rated at closer to 2 hp, he says.

With the DOE rule, another type of horsepower is being used to measure pumps — hydraulic horsepower (HHP). This figure is used to determine what WEF an individual pump must meet to comply.

Where total horsepower indicates the motor’s power, HHP measures potential flow and feet of head generated by the wet end.

To arrive at this number, the following equation is applied:

Hydraulic Horsepower= (Gallons per Minute x Feet of Head) / 3960

Instead of the traditional horsepower ratings that come in ½-horsepower increments (1 hp, 1½ hp, 2 hp, etc.), HPP will be shown in decimals up to two places for more precision. Instead of 1½ hp, you might see 1.67 HHP.

Pumps are tested at their highest speed to determine their performance based on the hydraulics of a 20,000-gallon pool with 2-inch plumbing and a cartridge filter. So HPP will not tell you how the pump will perform in your specific application. Instead, it provides a more precise and reliable means of comparing the performance of one pump to the other.

This means that two pumps of the same basic horsepower may have to test for slightly different WEFs, because of differences in HHP. “Quite literally every single pump on the market has a different WEF score they need to meet, unless it’s just the same pump rebranded,” Jones says.

⦁ ENERGY STAR Update

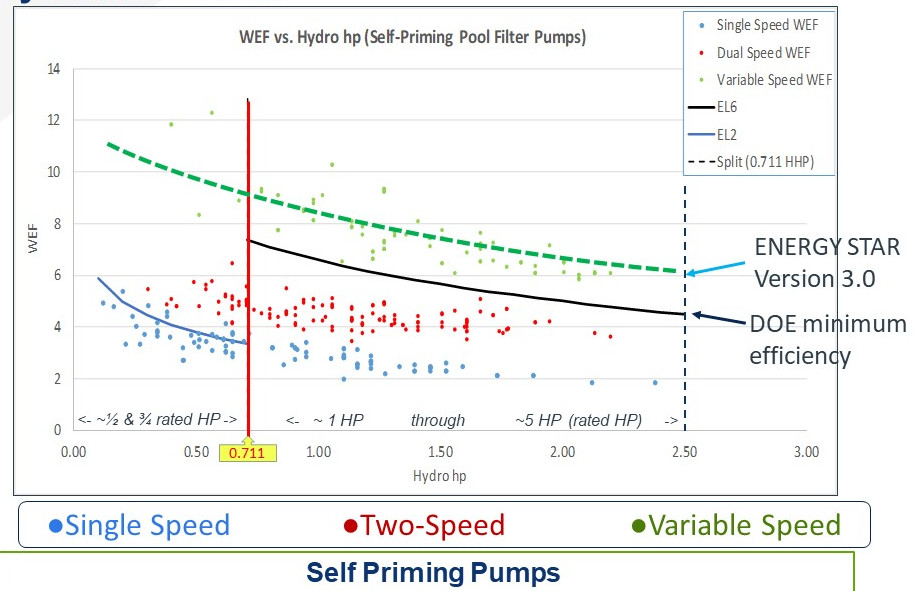

The point of ENERGY STAR is to reward those who purchase more efficient products than the average consumer. However, once the new DOE rule takes effect, virtually all pool and spa pumps sold on the market will align with current ENERGY STAR standards.

ENERGY STAR standards used to line up with the DOE minimum efficiency. For the newest version, ENERGY STAR 3.0, they've been raised to reward those who purchase the most efficient pumps.

For this reason the ENERGY STAR standard has been upgraded. The new 3.0 edition becomes effective July 19. Industry observers worry that utilities will stop offering rebates on ENERGY STAR 2.0 products that are still on the shelves. Representatives are working with utility companies to promote the continued recognition of ENERGY STAR 2.0 to allow for currently stocked product to sell.

“A consumer could buy that product, which has the blue EnergyStar sticker on it, then when they apply for the rebate, the utility might say, ‘That was EnergyStar 2.0. We’re only offering rebates on EnergyStar version 3.0.’ That’s the sort of minutiae that consumers shouldn’t have to [suffer].”

⦁ Replacement motors should be next.

When the DOE first published its pump rule in 2017, the industry and energy-efficiency advocates made clear their intent to promote similar language for replacement motors. They worried that people would sidestep the energy rule by replacing motors rather than purchasing a compliant pump.

Industry representatives and DOE staff developed language pertaining to motors, hoping it would gain approval and become effective on the same date as the pump language. However, the pump language had been adopted with President Obama in office, while the motor language was proposed during the term of President Trump, whose philosophy was much different. Officials removed the requirements and made everything optional, taking away its teeth, as one industry observer said. The DOE never submitted it for final approval.

With the Biden administration in place, industry reps plans to work again with DOE in the hopes of reviving the requirements, but it almost certainly won’t occur by July 18. Even if it did, there’s usually a window of several months before such a change would be implemented.

“We do think that what was originally proposed would be favorable to a new administration,” Farlow says.

This doesn’t apply to professionals in California, which plans to begin regulating replacement motors on July 19 according to its Title 20, Petty says.

⦁ Manufacturers’ transition plans

It’s not a simple thing to change production lines to different SKUs, so producers will have to gradually transition, dedicating more and more of their operations to compliant pumps, and phasing out obsolete models by July 18.

As far as models that will fall out of compliance, manufacturers have adopted different approaches. In January, Pentair stopped taking orders for non-compliant pumps in North America. Hayward stopped offering guarantees to fulfill orders after an early March deadline.

⦁ Builders, service pros and retailers: Figure out a plan

Those looking to sell compliant pumps now can promote ENERGY STAR-certified models, all of which will comply with the rule, Farlow says.

Start now determining what pumps will replace those you commonly use. Most major manufacturers have released lists of pumps that will cease production and what models could make suitable alternatives. “This regulation is SKU-specific,” Petty says. “It impacts every SKU differently, therefore, it impacts every pool professional differently.”

Professionals will have to develop a game plan for certain applications, such as spa booster pumps, or waterfeatures that traditionally would rely on single-speed 2hp pumps, as those will no longer be produced.

Start doing these things sooner rather than later. When this rule was first finalized, professionals figured it would be months before all non-compliant pumps made before July 19 would sell out. When the pandemic demand hit, that expectation window shrank a little. Then the Texas freezes occurred in February. Considering the amount of product it will take to make the Lone Star State whole, some wonder if any of the old pumps will be available on July 20.