Imagine a world without the ground-fault circuit interrupter (GFCI).

It’s easy to take this remarkable safety workhorse for granted, but the folks at the National Electrical Code (NEC) certainly don’t. That’s why the latest NEC guidelines take Article 680 compliance to a whole new level.

However, proper use of GFCI outlets is only one aspect of code compliance. Rather than looking at these new standards as a chore to complete, pool builders and service professionals can use them as an opportunity to improve outdated pool components and promote long-term safety.

Consider these common electrical safety opportunities as you work towards code compliance this pool season.

1. Inappropriate Splicing. The NEC outlaws splicing of underwater wire connections. Only a continuous cord is acceptable. For example, don’t try to install a new light by splicing the new wire to an existing cord or into a listed and labled pool light junction box.

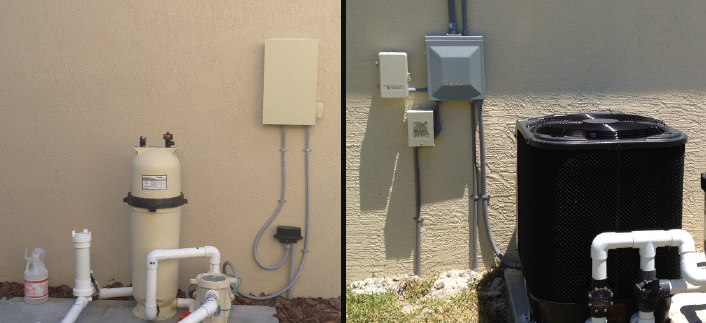

2. Scattered Controls. Pools built 10 or 15 years ago often have components that are strewn across the pool. By organizing timers, transformers and other devices into a single enclosure, professionals can make maintenance easier while creating a cleaner aesthetic (see photo).

Pool transformer components organized in an enclosure (left) versus separately-mounted components (right).

3. Properly Protecting GFCI Wiring Devices. GFCIs should be shielded from the elements with a properly-rated in-use weatherproof cover and routinely tested. Select manufacturers even offer a variety of colors and low-profile options to match home décor.

4. Excess Voltage. Low-voltage lights require a transformer or power supply that’s listed specifically for that application. Make sure the transformer has a grounded isolation barrier for high-voltage winding or double-insulated.

5. Streamlined Components: Rather than adding to an already-cluttered pool area, look for ways to simplify components, such as integrating a two-in-one junction box transformer for low-voltage lighting needs.

6. Poorly Bonded Equipment. Maintain the integrity of the bonding grid. Some installers attach just one wire and may leave others loose, thinking a single-wire connection is enough.

7. Missing Liquid-Tight Connectors. These tube-like jackets and their connectors protect wires from rubbing against equipment edges and components with corners. The connectors reduce the risk of a live, exposed wire from touching the metal housing.

Evolving to a New Standard

There was a time when meeting standards like NEC Article 680 meant installing unsightly junction boxes, load centers, transformers, and weatherproof covers. Pool and spa professionals had to choose between sound aesthetics and code-compliant performance.

At least one U.S. manufacturer of pool and spa control equipment has set out to prove that pool builders, service technicians and distributors can have the best of both worlds. Illinois-based Intermatic offers NEC compliant, CSA listed (one of several company NRTL distinctions) load centers, junction boxes, transformers, and weatherproof covers that simplify pool management with good looks and functional performance.

For example, the company’s fresh take on a standard pool component, the weatherproof power outlet cover, gives a sleek new look to a clunky poolside mainstay. The code-compliant cover features an innovative see-through window that smartly retracts into the cover when the outlet isn’t in use.

“Homeowner needs have evolved considerably over the last 15 years. Today’s emphasis on blended indoor/outdoor backyard environments puts a greater importance on aesthetics and electrical control simplicity,” notes Jon Payne, zone manager at Intermatic. “Pool professionals can make their jobs easier and ensure happy clients by seeking out solutions that promote smart design and still remain code compliant.”

It’s good to know the GFCI has never been so well supported by pool control equipment manufacturers. Learn more on how to improve pool control simplicity, looks, and performance.