Variable speed pump (VSP) technology has made quite an impact on the pool and spa industry in the last few years. With rebates on the rise and a Department of Energy ruling that will require use of energy-efficient pumps beginning in 2021, their demand is only expected to increase.

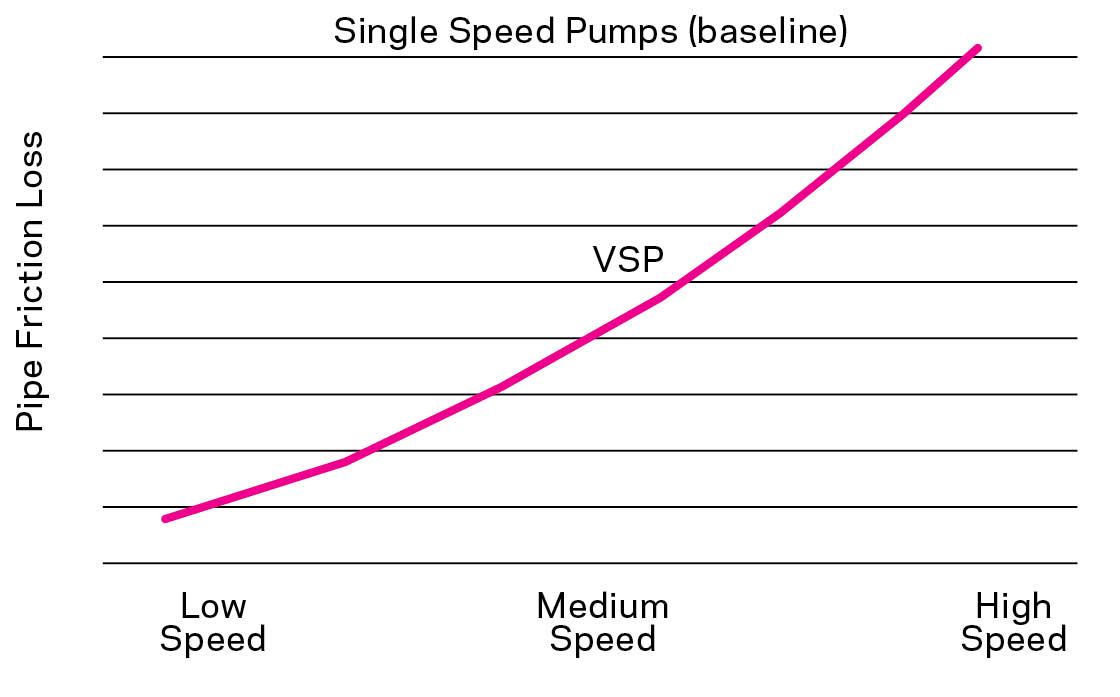

VSPs deliver a wide range of benefits compared to single-speed pumps. The significant energy and cost savings are well-known. (By cutting the speed in half, you can reduce energy used by 7/8, due to the Pump Affinity Law.) Below, we outline other benefits to consider when selecting your next pump.

1. VSPs improve filtration.

Irrespective of the type of filter being used, performance improves when water moves through it more slowly, as the opportunity for particle removal is increased. This can translate into less filtration time, even at lower pump speeds, leading to even more energy savings.

Conversely, at higher flow rates, particles can be forced though the filtration media and channeling (i.e. voids) can occur. This leads to lower filtration efficiency.

2. VSPs make turnovers more effective.

Turnover rate is defined as the time required to filter the equivalent volume of the entire pool. But, practically speaking, all water molecules are not passed through the filtration system during a single turnover. Instead, the filtered water returns to the pool, where it is mixed with unfiltered water. This substantially increases the time and number of turnovers needed to filter all the water in a pool. That’s why four turnovers per day are often required by local health codes for commercial pools.

So how are pool water mixing and VSPs related, and why is it important? With higher flow rates, water is mixed more thoroughly, so less time elapses before filtered water mixes in and goes through the skimmer to be filtered a second time, even before some water molecules were filtered once. At low flows, on the other hand, one can picture a wall of clean water moving slowly toward the skimmer, giving the filter system a chance to clean the dirty water before too much mixing occurs. In this scenario, less time is required to filter the whole pool, so the filter efficiency of each turnover is improved.

3. VSPs improve high-flow operations.

Not all VSP advantages spring from low flow rates. Some come with higher flow rates.

Heating represents one example. Heat transfer from the walls of the metallic tubes to the moving fluid inside improves as the flow rate increases. This occurs because of a thin layer, mere microns thick, of near-stagnant water at the wall of the tube. As the flow rate increases, the thickness of this “boundary layer” becomes thinner, so heat transfers more efficiently.

Suction cleaners also require higher flow rates. Insufficient flow through the skimmers leads to inadequate suction, and debris cannot be lifted through the hose. Furthermore, many suction pool cleaners utilize a diaphragm that rapidly opens and closes as water is drawn through a relatively narrow throat opening. Higher flow rates are typically required to generate the force needed for diaphragm operation.

Chemical feeders, too, benefit from higher flow rates, which encourage more rapid mixing and homogeneity of the added chemical with the water. In the case of chlorine or acid addition, for example, it is desirable to encourage dispersion of these chemicals quickly to create a uniform chlorine residual and pH.

To minimize time needed to operate the pump at high speeds, thereby reducing operating costs, the best choice is to conduct heating, chemical-feeding and suction-cleaner operations at the same time.

4. VSPs optimize waterfeatures.

Bubblers, laminar jets, waterfalls, spillways and other waterfeatures require different speeds to create the exact aesthetic desired. Imagine a water slide with little water flow: That would lead to a rather uncomfortable ride. Or, how about a laminar deck jet whose water flow is so poor that is does not even reach the pool? Waterfeatures require that the user “dial-in” the speed that extracts the best performance. VSPs permit this seamless optimization of any type of waterfeature.

5. VSPs improve UV system performance.

Ultraviolet light disinfection systems have grown in popularity. Interestingly, UV disinfection performance has a logarithmic dependence on flow rate: As the flow rate decreases by a factor of two, performance increases by 100!

Let’s take the example of a UV system capable of inactivating 99% of microorganisms at 50 gallons per minute. At half the flow rate, the system would inactivate 100 times that amount, or 99.99%.

We know that the energy or cost required to operate the pump at the lower flow rate will be much less than at the higher rate. So, even accounting for the longer running time for the UV system and its associated electricity consumption, the cost of operating the pool at the lower flow rate is less, and the bacteriological quality of the water is much improved.

6. VSPs are less noisy.

Sound reduction is a significant benefit of VSPs. When operated at lower speeds, pool pumps produce less noise.

At full speed (the only option for single-speed pumps), many units emit noise levels of 65-90 decibels at about a 1-meter distance from the pump. For comparison, a whisper has a noise level of about 20 dB, whereas normal conversation is 60 dB, and a vacuum cleaner is 80 dB. Noise drops off as the distance from the pump increases. A reduction of only 10 dB is associated with a 90% decrease in noise intensity. It has been observed that decibel levels can go down 30% or more as the pump’s impeller speed is reduced.

7. VSPs have a longer product life.

Pump motors don’t last forever, but running at lower speeds is less taxing on them, leading to increased operating life. Heat is the primary enemy of most motor components. Just as power and noise are greatly reduced at lower speeds, so too is heat generated by the motor, leading to considerably less stress on mechanical and electrical components.