A high-rate sand filter that’s backwashed regularly can go many years without needing fresh sand.

High-rate sand filters clean water via a process known as depth filtration, meaning that dirt penetrates the sand bed and is captured in the tiny spaces between grains of sand.

Backwashing is key

How do you know when it’s time to backwash?

One obvious clue is cloudy water. When the pool becomes murky, the filter may be dirty, the circulation may be poor or there may have been a chemical reaction. A far better clue, however, can be found with the filter’s pressure gauge(s).

If the system has inlet as well as outlet pressure gauges, you will note only minor pressure differentials — perhaps 3 psi — when the filter is clean. As the sand bed begins to load up with dirt, that differential will begin to increase. In most high-rate sand filters, it’s time to backwash when the pressure differential reaches 18 to 20 psi.

But if the system has only an inlet pressure gauge, you should backwash when the pressure increases by 8- to 10 psi from initial post-backwash readings. The best idea is to mark the pressure gauge with a grease pencil right after a good backwashing — or maintain a record of the running pressure on a route sheet as you monitor filter cycles.

These filter cycles can be affected by different factors, ranging from heavy bather load and algae to wind-blown dirt and debris. In addition, a sand filter on a newly plastered pool will clog quickly with plaster dust, which often precipitates out of new plaster during start-up procedures.

This fine plaster particulate can easily clog a sand bed and greatly reduce the length of initial cycles. In fact, when first starting a sand filter on a fresh pool, it may be necessary to perform an extended backwash of two to three times the normal duration to rid the sand bed of the bothersome dust.

Watch that water flow

Backwashing is a simple matter of reversing the flow through the filter by sending water up through the underdrain or laterals and diverting the outlet water to waste.

The procedure is simple: Turn off the pump to avoid damage to plumbing or valving, then turn the control valve to the backwash position and restart the system.

Given a typical flow rate of 15 to 20 gpm per square foot of filter area, most manufacturers recommend backwashing for two or three minutes. As always, it’s a good idea to consult manufacturer service manuals for specific backwashing procedures.

After backwashing, with the pump off, set the valve to the “Rinse” setting if you have a multiport valve. Start the pump and operate for approximately 30- to 60 seconds. This assures that all dirty water from backwashing is rinsed out of the filter to waste, preventing its possible return to the pool. Stop the pump, set the valve to “Filter” and start the pump for normal filtering.

Charged up for action

To get a sand filter system off to a good start, proper charging of the sand is essential. Here are the basic steps:

First, get sand of the proper size. Most filters use sand that’s typically .45 to .55 millimeters in diameter, also commonly referred to as “pool grade No. 20 silica sand.” (Note: Some filters also use gravel in the filter bed. Consult manufacturer for proper gravel specifications.)

To keep sand out of the circulation system, cover vertically exposed plumbing or standpipes with protective caps such as coffee or soup cans. On some models, you’ll also need to put the lateral assembly in the tank before adding sand. That way, internal plumbing seats properly when the valve on the filter dome is reassembled.

Just before adding sand, some manufacturers recommend filling the tank bottom with a few inches of water to cushion the sand as it’s poured in. Also, cover the lateral assembly with pea gravel before adding the No. 20 silica sand to help prevent damage.

Pour the sand gently through the top of the filter tank. A good rule is to leave 10 to 12 inches of freeboard — that is, the space between the top of the sand bed and the bottom of the diffuser assembly. Adequate freeboard prevents sand loss during backwashing, enabling the filter to work effectively.

Service and installation manuals offer tips to help you charge the filter. For example, some recommend holding down the vertical standpipe so it isn’t dislodged as the sand is added. Remove the protective caps and replace the top valve or dome on the filter tank. Some assemblies are threaded into the top of the tank; others are secured by a clamp assembly. All assemblies use O-rings to create a good seal; an appropriate O-ring lubricant will help ensure that seal.

A closer look at valves

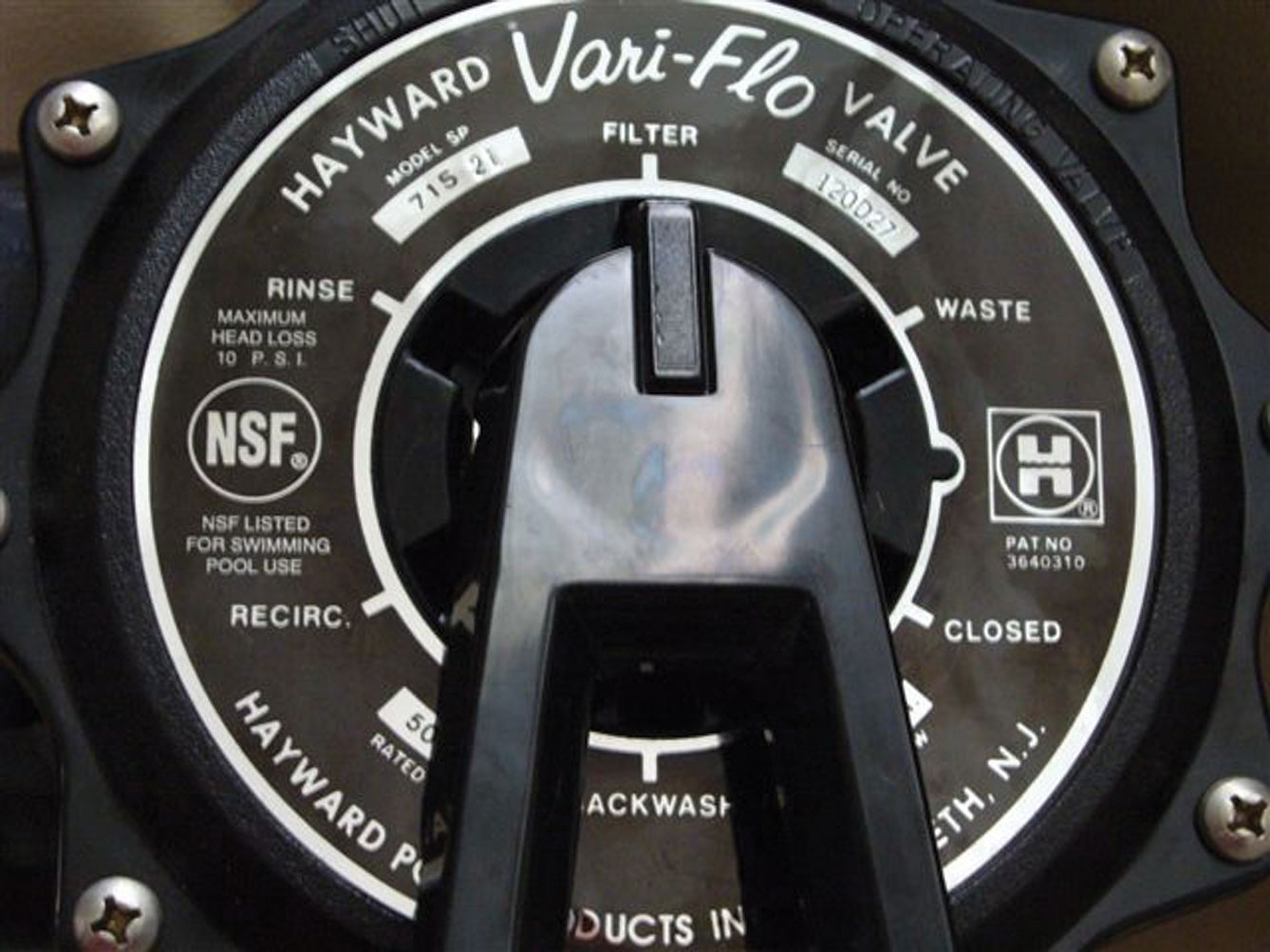

Sand filters use one of two types of valves: a multiport valve (which can be top or side mounted) or a side-mounted slide valve (sometimes known as a push-pull valve). A side-mounted model is strictly a two-function valve: filter and backwash modes only. The type of valve used is often dependent on regional differences, but in general, you’ll likely find more multiports because they can also appear on DE filters.

So let’s take a look at the positions found on a multiport and what they mean:

Filter mode: This is the mode the filter will be set to most of the time. It’s for filtering the water. In this mode, the valve directs the water to the top of the filter, where it compresses and flattens down the sand. Contaminants are removed as the water makes its way to the bottom laterals, out of the filter and back to the pool.

Backwash mode: Backwash mode: This is the one you turn to when cleaning the filter and its medium. You know it’s time to backwash when the pressure gauge rises 8- to 10 psi above what it normally reads when the filter is clean. In this mode, the valve directs the water to come out the bottom laterals, reversing the flow through the tank. This causes the sand to separate and lift about 7 inches above its normal position while releasing the trapped debris into the water, allowing it to exit from the filter and go out the waste line.

Rinse mode: Water is directed by the valve to the top of the tank, just like the filter mode. The sand is re-seated back in place while still sending water out of the waste line, thereby reducing the chance of particulate blow-back to the pool when the valve is moved back to the filter position after backwashing.

Recirculate: Water is directed through the valve only, not the filter. This is a position to use during certain pool cleanups and chemical treatments, when you don’t want the water contaminating the sand.

Waste mode: This position bypasses the filter and sends all the water out the waste line — a great setting for vacuuming pools after an algae treatment, and new sand addition or filter start-ups.

Operation tips

Now that we are clear on which functions the valve modes perform, here are some dos and don’ts that you can follow to help keep sand filters running smoothly:

Do: Be aware of the filter pressure when it is clean. Watch the pressure gauge. Backwash when you see an increase of 5 psi, possibly as much as 10 psi on some filters.

Do: Backwash long enough to get the job done right. Wait until the water is clear coming out of the waste line or shows clear in the sight glass on the side of the valve. Backwashing can use 50 to 300 gallons of water, so pay attention. In addition, be aware of local codes regarding pool water disposal. Many communities outlaw such procedures, and you could be hit with a stiff fine. Check with your local authorities on the accepted methods in your town.

Don’t: Moving the valve handle while the pump is operating should not occur. Never move the handle of the multivalve while the pump is pushing water through it. It will damage the valve and possibly other equipment. Fully depress the valve handle when turning it to prevent damaging the valve seat gasket.

Don’t: Avoid excessive backwashing. A feature of this filter is that it operates most efficiently during mid-cycle. As it collects particulates in the sand bed, debris caught up in the sand actually helps the filter work more effectively. Too much backwashing will reduce the filter’s efficiency.

Don’t: Avoid vacuuming a pool with the filter in backwash mode. You could plug up the laterals at the bottom of the filter with dust from the new pool surface. This restricts flow to the filter, resulting in inefficient operation. All the sand would have to be removed to unclog the laterals.

Do: Protect the laterals while replacing sand (usually using No. 20 silica). Fill the tank with about a foot of water to shield the laterals and cover the upper diffuser, or stack pipe, so that sand doesn’t get inside.

Do: Fill the tank with sand to about half-full and keep it level. Models may vary, but the general rule is 12 inches from the top of the sand bed to the bottom of the valve or top diffuser.

Do: Start the filter in the rinse cycle for 1- to 3 minutes after starting a new filter or after replacing the sand in an existing one. Some small particles and impurities may still blow back to the pool. If this happens, always vacuum the debris to waste or you may keep sending it back to the pool.

— Lawrence Dow, Hayward Pool Products.

PSN thanks Hayward Pool Products for its assistance in preparing the sand filter article