When selecting the correct sand filtration system for a commercial project, you must pay close attention to every step of the process. Whether the project is a new waterpark or renovation of a smaller commercial pool, certain aspects of the job require a detailed plan of action.

Size and space

Available space plays a key role. The floor plan of a filter room should begin with a layout of the filter footprint. In an existing filter room, you must consider access to the area, with doors and stairways being major factors. With a new facility, construction costs become the main issue.

However, in either case, don’t allow space limitations to force you into using an inadequate filtration system.

To begin sizing the filter, you need to determine how many gallons of water are in the pool. For a list of formulas for calculating the volume and capacity of the various pool shapes, turn to the prior article.

In a rectangular pool that’s 75 feet long and 45 feet wide with an average depth of 5.6 feet, you would calculate the formula as follows: 75 x 45 x 5.6 x 7.48 = approximately 141,370 gallons.

The turnover rate

Next, establish a turnover rate. This represents the time it takes for all the pool water to circulate through the filtration system. State and local health departments govern this rate, and they can decree that it runs from 30 minutes to eight hours, depending on the type of pool.

Make careful calculations when it comes to a waterpark pool that has a zero-depth or beach entry. The beach entry may have a different turnover rate (usually two hours) than the rest of the pool. The splashdown area in this type of pool usually has a turnover rate of four hours. For this information, you need to check with your local health department.

The flow rate

Turnover rate determines the gallons per minute (or flow rate) for the pool. It will then be used to figure out the final number of square feet of filter area needed.

Local health departments determine the gpm per square foot of filter area. This number is usually 15 gpm per square foot, but can be as high as 20 gpm per square foot.

The lower the gpm per square foot, the less time the end user will spend backwashing in the filter room. This saves time, water and chemicals.

The formula for determining “gallons per minute” works out thusly: number of gallons ÷ turnover rate. Using the previous example of a 141,370-gallon pool, let’s assume the health department has given you a turnover rate of six hours. Because you want to find the flow rate in gpm, you must change the six-hour turnover rate to 360 minutes (6 hours x 60 minutes). Then you must divide the gallons by the numbers of minutes: 141,370 ÷ 360 = 392.7 gpm.

Sizing the filter

Once you know the gpm flow rate, divide it by the gpm per square foot as determined by your local health department. Using 15 as an example, here’s the formula: 392.7 gpm ÷ 15 gpm per square foot = 26.18 square feet of filter area required. Keep in mind that multiple filters may be used to obtain the proper amount of filtration area.

Now you have the size of the filter based on the square footage needed — not by the turnover rate alone. This is the most important lesson to remember. Don’t be afraid to use the gpm per square foot of 13.5. In the long run, you and your customer will benefit.

Remember, the lower the gpm per square foot, the longer the filter cycle you will have before backwashing. Slowing down the gpm per square foot will produce better water quality, too.

Depth of filtration

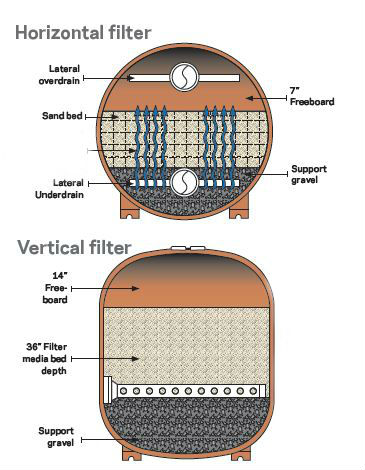

We have discussed the importance of using a lower gpm per square foot, but you also need to examine something often overlooked in the past few years: depth of filtration. You must choose a filter that reduces your customers’ time in the filter room and conserves water by lengthening the cycles.

Equipment makers know the importance of depth of filtration vs. surface or shallow filtration. A deeper sand bed will produce better water quality by allowing a longer contact time with the filter media. It drives the dirt farther into the sand bed, which lengthens the time between backwash cycles and reduces the possibility of channeling.

When choosing a high-rate sand filter, it’s important that the ability to trap dirt is measured by the depth of the sand bed, not just the surface area of the filter. Therefore, when considering a filter for your project, a vertical filter becomes a better choice than a horizontal one. Consider horizontals only for renovations or when verticals will not fit due to space limitations.

Author: Tim Warren was formerly vice president of manufacturing and commercial sales at AstralPool, a brand of Fluidra, a filter manufacturer based in Jacksonville, Fla.