Since the introduction of controls using Printed Circuit Boards (PCBs), techs have had an increasingly difficult time performing repairs on controls. Field repairs on these types of components are nearly impossible.

However, that’s not to say that there’s nothing that techs can do to solve the problems. With a little knowledge and a few tests, they can ensure many failures do not recur once the system is again operating.

1. Be sure the control is the problem

Nothing wastes more time than working on the wrong portion of the equipment system. Certain problems can be tied to the control and others can’t. Unfortunately, because solid-state controls are misunderstood, they often are blamed for failures before the proper steps have been taken to isolate the true source of the problem.

Another frustration occurs when the PCB is really a symptom of the failure, but not the actual cause. While you may fix the issue temporarily, the failure will recur.

For example: The high-speed pump can’t be selected and voltage leaves the PCB. After you replace the circuit board, the unit runs and you return the spa to service. Three days later, the customer calls back with the same complaint. While the PCB needed replacement, the fact that the output relay failed was not the fault of the PCB — the pump caused the relay issue. The pump should have been checked for proper current draw after the PCB was replaced.

2. Understand how the control operates

The functions of spas haven’t changed appreciably since they were first introduced. As such, there are still some issues that can be overlooked if techs don’t understand the functionality of the specific system they are troubleshooting. For example:

a. Troubleshooting an ozonator issue can be futile if the tech doesn’t recognize that the system only turns the ozonator on while in a “filter cycle.”

b. Techs fail to see that the temperature of the source water was less than 45 degrees, and the unit believes it is in “freeze” mode.

c. The customer reports that the blower and booster pumps come on and off intermittently. Techs could waste time if they aren’t aware of a “purge cycle.”

d. Techs may misread an error message. Some systems allow the display to be inverted so that the temperature or messages can be read from inside the spa.

3. Isolate the problem to a control component

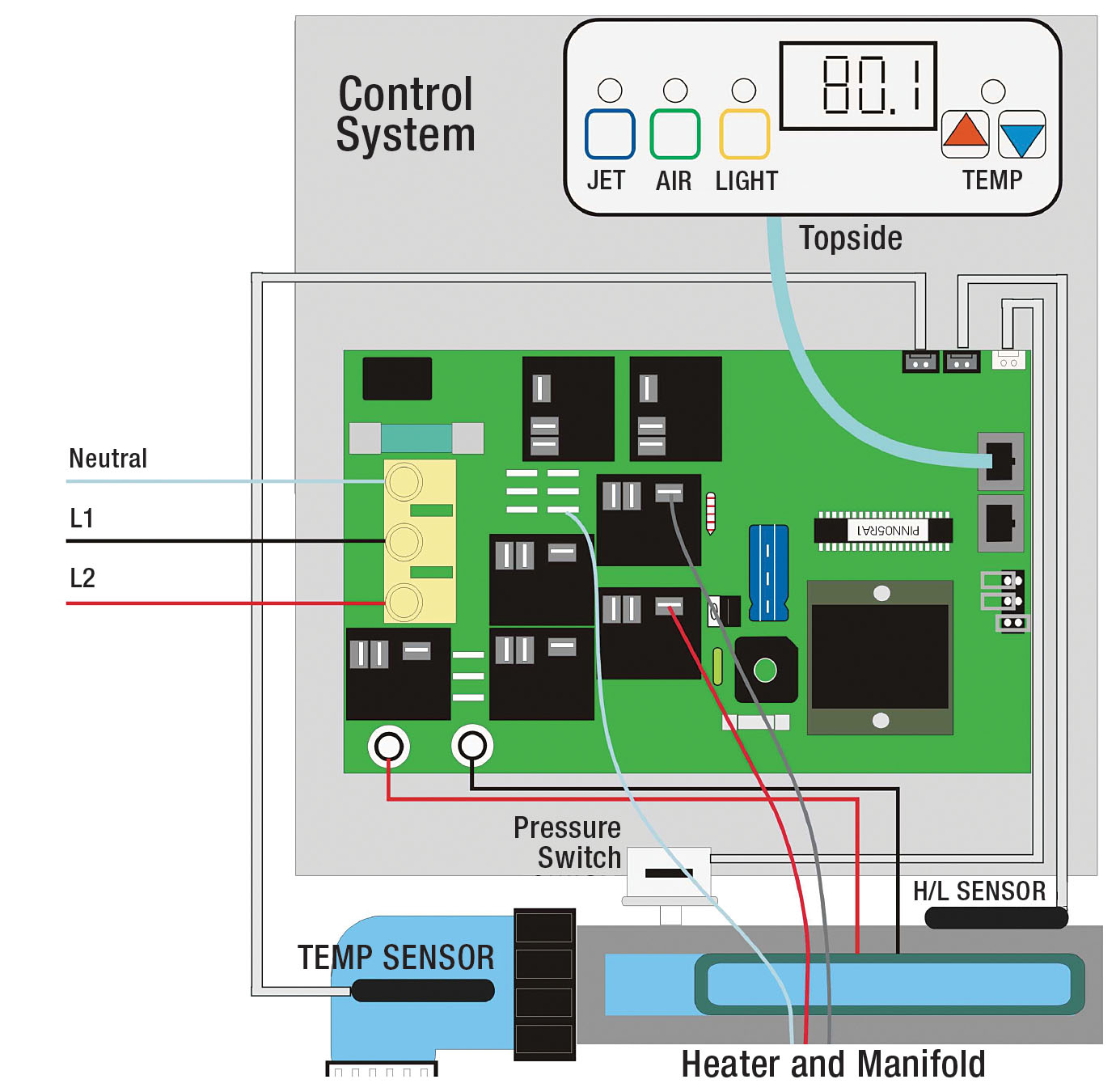

For the most part, each solid-state system will have a PCB, topside and sensors. Isolating the problem to one of these components is about all techs can hope to accomplish in the field.

Sensors: Most electronic controls built today use at least three sensors: One for temperature control, one for freeze- and high-limit protection, and another for flow detection. They come in as many shapes and sizes as there are controls.

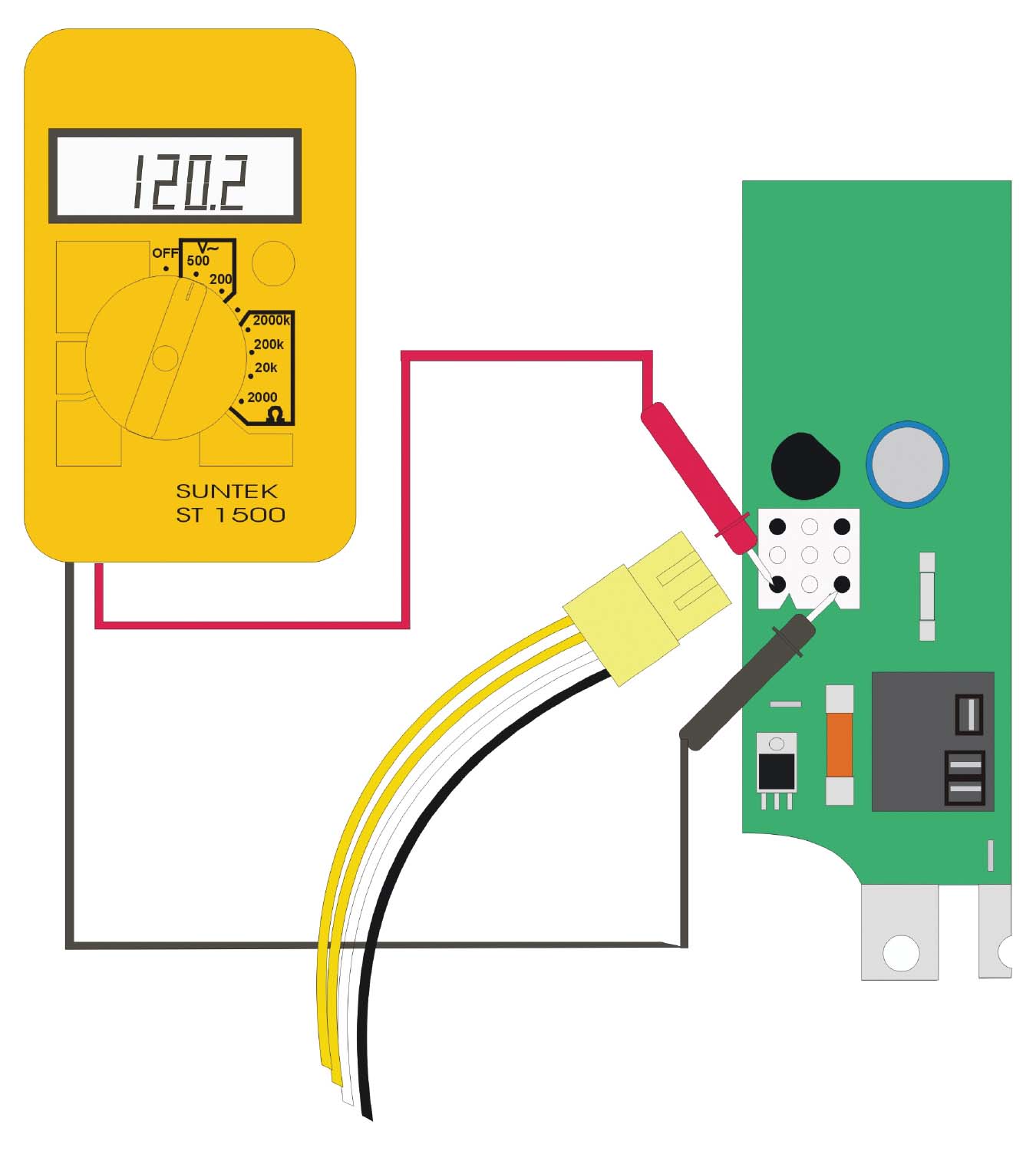

Powered up: This is an example of how to check the transformer for voltage reaching the primary.

Most manufacturers use the same base component for both sensors (Gecko is an exception). Temperature sensors can’t be bypassed to isolate issues. If all else fails, comparing the resistance of the two sensors in open air should give you an indication if there is an issue with one. Since they are basically the same component, they should read close to the same resistance value.

Some controls also use a flow, vacuum, or pressure switch input to protect the heater. This input is an open or closed type of connection, and can be bypassed to simulate operation if done when the logic of the PCB expects to see that condition.

Some newer spas use a safety feature that disables the spa control if too much suction is detected. However, these also can fail and shut the system off. Most of these systems work with a vacuum switch in the normally open position.

Topsides: These panels also come in myriad sizes and styles. Some are interchangeable and others are not — even with topside models from the same maker. It’s impossible to know what is swappable and what isn’t without manufacturer information. The best way to evaluate the operation of a suspect topside is to replace it.

Printed Circuit Boards: Some PCBs use on-board transformers to step down the voltage; others have separate transformers that plug in.

Specific to the make and model of the control, the programming of the microcontroller IC determines the functions and sequence of operation. This is usually identified by the code printed on the label pasted to the chip on the PCB.

Troubleshooting steps

1. Always verify that the service voltage reaching the control is correct: 240VAC between L1 and L2, 120VAC from L1 to neutral and L2 to neutral, 120VAC from L1 to ground and L2 to ground and 0VAC from neutral to ground. You can’t continue until the service measures properly.

2. Unless the system is completely dead (no display, no functions), verify the reported symptom by operating the unit as thoroughly as possible. By seeing all the problems, you can more accurately choose a point from which to start.

3. If the system is dead (no display, no functions) and the proper voltage is reaching the control, try shutting down the service for 10 seconds and resetting to see if anything operates or if you hear any relays trying to latch. If nothing happens, shut down the service again, and check the system and transformer fuses.

4. If both fuses check out but no functions or relays react when service is applied, then it is likely that either the PCB power supply circuit or transformer has failed.

5. If the PCB has an integral transformer, the only options are to send it to a repair facility or replace it.

6. If the transformer plugs into the PCB, check for proper input from, and output to, the PCB by measuring the voltage on the primary (should be either 120VAC or 240VAC depending on the PCB) and the secondary (usually between 12 and 15 volts AC).

In most cases, you’ll have to check for secondary voltage while the transformer is plugged into the PCB by making contact with the crimped on the ends of the wires going into the transformer plug.

7. If the transformer primary voltage is bad, recheck the transformer fuse and holder for proper connection. If all checks out OK but no voltage reaches the transformer, the PCB has a bad trace or broken component pin. The only options are to send the PCB to a repair facility or replace it.

8. If the primary voltage check out OK but the secondary voltage is bad, try replacing the transformer. If replacing the transformer doesn’t solve the issue, then the only options are to send the PCB to a repair facility or replace it.

9. If primary and secondary voltages check out but there’s no reaction from the topside or relays when power is reset, then, again, the only options are to send the PCB to a repair facility or replace it.

Additional troubleshooting

If there is proper voltage reaching the control, the unit comes on and some functions operate while others don’t, then it becomes a case of finding out which of the three component types are causing the issue.

Sensor failures: First, look at the topside display for possible error codes or obvious erroneous indications. In most cases, if a sensor is causing the issue, there will be some indication on the topside.

Note: Remember that flow and high-limit errors can indicate an issue with water flowing in the system. Also, verify the issue rather than assuming the device has failed. Failure to recognize such issues can potentially damage the loads or control.

For example, errors such as Sn, Sn1, Sn2, Prr, OP (check the owner’s manual to learn error codes) indicate a failure of the temperature or high-limit sensors. Often this locks out all other functions until the issue is fixed. Some spas don’t use alphanumeric characters, but have flashing LEDs indicating a failure by the duration or pattern. In some cases, the sensor may not be totally bad, but out of tolerance. In these cases, you may get an abnormally high reading, or an over temp error (OH, HL). The same holds for a spa that continues to heat; indicates a freeze condition (Fz, Fr, ICE); or signals a low temperature when the water is warm.

If you suspect a failed temperature or high-limit sensor:

1. Turn off the service, swap the sensor positions on the PCB (not possible on Gecko systems) and see if the display changes when voltage is reapplied.

2. If the display changes, then one of the sensors is bad and should be replaced.

3. If no change is observed, then it’s likely an issue with the PCB. The only options are to send the PCB in to a repair facility or replace it. (Note: On Balboa M7 systems, swapping sensors may not change the display indication, even if there is a problem. Compare resistance readings, if in doubt.)

4. If swapping sensors is impractical or impossible, power down and disconnect both sensor connections from the PCB. Compare resistance across the two sensors; they should be close in value. If there is greater than a 500 ohm difference, then there is a large temperature difference in the spa or one sensor is out of tolerance. (Note: This comparison isn’t possible on Gecko sensors.)

5. If you can’t determine which sensor is malfunctioning by swapping connections or measuring resistance, then replace both sensors, one at a time, until the system returns to normal.

Pressure / Flow Switch Failures Flow errors also can lock certain functions. Some indicators are codes Flo, FL, E4, FLC. Some systems errors are indicated by an LED. These types of errors are often the easiest sensor failure to troubleshoot. Note: There are some systems that do not have an open switch error code, only when the switch is “shorted” or closed.

In the case of a “shorted” or closed flow or pressure sensor:

1. Disconnect the flow device connection. If the error indicates flow without pump operation, then disconnecting the flow/pressure switch connection should change the state of the control.

2. If you see a change, evaluate the operation of the flow/pressure device. (Pressure switches should not require readjustment after initial set up. If the device does not operate correctly or requires adjustment, then something in the plumbing has changed or the device is failing).

3. If no change is observed, then it is likely an issue with the PCB, and the only options are to send the PCB in to a repair facility or replace it.

In an “open” flow or pressure sensor:

1. Once the connection has been removed, ensure that the pump is running.

2. Create a short between the pins of the PCB connection with an insulated screwdriver or pair of pliers.

3. If the system starts to operate correctly, evaluate the operation of the flow/pressure device. (Pressure switches shouldn’t require readjustment after initial set up. If it doesn’t operate correctly or requires adjustment, then something in the plumbing has changed or the device is failing.)

4. If shorting the flow connection pins doesn’t change the symptoms, then it’s likely an issue with the PCB and the only options are to send the PCB in to a repair facility or replace it.

PCB or topside failures: Once the sensors have been eliminated as the cause of the issue, next determine whether the PCB or topside is causing the failure.

Techs often can tell the difference between a topside and PCB problem based on the symptoms. The following steps assume that a physical inspection and incoming service voltage have been verified. Depending on the severity of the initial cause of the failure, both the topside and the PCB could require replacement. (This is rare.) There are isolated cases where plugging a bad topside into good PCB can damage the new PCB. In older Vita Spas, it is recommended to replace both topside and PCB if you are not sure which item is faulty.

Note: Unfortunately, the reported symptoms may not always clue you into the problem. If all else fails, it may be necessary to have a spare of each to swap out to isolate the problem or see if the symptoms change. Also, when testing, be sure to inspect the cable and PCB connections for moisture, or broken or bent pins/conductors.

Below are some signs techs can use to determine if the PCB or topside should be suspected as the culprit.

1. No display and no button functions

Suspect = PCB

• If no relays close or loads are selected when service is applied

• If the system and transformer fuses check out OK

Suspect = Topside

• If the relays close and initial loads are selected with service, but no other displays or selections can be made

Tip: If the PCB performs a normal start-up routine but the topside never “comes alive,” it indicates that the PCB is capable of running.

2. Bad display/no display, but some buttons work

Suspect = PCB

• If display flickers or fades in and out

• If pressing temp up/down doesn’t affect the appearance

• If the temp can’t be regulated

Suspect = Topside

• If the display is completely blank or wrong, but steady

• If there is a change in appearance when temp buttons are pressed and/or the heater can be set on and off

Tip: The temp/display functions are often separate from the basic buttons and can often be used to verify a display issue.

3. Good display, but unable to select or deselect a single function.

Suspect = PCB

• If an icon or LED appears when a button is selected or if you hear a relay click, but nothing comes on

• If you remove the topside and cycle power, and the load is still energized

• If neither temp up nor down works

Suspect = Topside

• If icons, LEDs, and relays don’t change state

• If you can remove the topside and change the output of the PCB

• If only temp up or only temp down works, or one is selected constantly

Tip: If icons, LEDs or relays react to the buttons, it indicates communication from the topside.

4. Functions cycle or select/deselect themselves

Suspect = PCB

• If no icon or LED changes

• If the condition does not change with topside removed

• If the system locks up or restarts after several buttons pressed in quick succession

Suspect = Topside

• If the LED or icon cycles

• If removing the topside changes condition

• If the symptom occurs every time the same button is hit

Tip: If icons or LEDs react without pressing buttons, it indicates communication from the topside.