State of the Market Forces

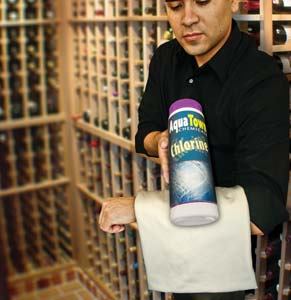

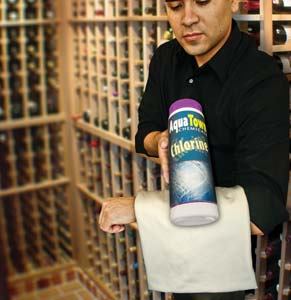

Chemical costs have risen significantly over the last year. Here is why.

Competition is unyielding for pool and spa chemical dealers. So how do retailers keep business healthy?

How smaller stores compete with the big boxes on price.

Even as builders slash margins and drop prices to unthinkable lows, it’s never been more expensive to maintain a pool.

From the last summer through the beginning of 2009, the pool industry has seen aggressive price hikes for chemicals. The increases have cumulatively added anywhere from 15- to 30 percent to the cost of chlorine, algaecides and additives. Furthermore, these new costs come at a time when consumers are shoring up their budgets.

But for many, the price increases were an inevitable product of market pressures.

“At the end of the day, chemicals in this industry have been a bargain for a very, very long period of time,” says Manuel J. Perez de la Mesa, CEO of Pool Corp in Covington, La. “The prices have been artificially depressed.”

Although no one likes to talk pricing — Arch Chemicals declined comment for this story — the cost of making these products has been on a steady climb.

Without question, the biggest impact on price increases has been raw materials. The chlor-alkalai market has fluctuated wildly over the last 18 months, and pricing on isocyanurates has steadily increased. Packaging is another key factor behind price hikes. And fuel costs play a part as well, as chemical manufacturers pass on surcharges incurred from freight carriers.

Unfortunately, these costs may not be coming down anytime soon. But the following metrics provide a much clearer picture of the pool chemical marketplace.

In the pool industry, raw material costs are especially critical. Unlike other household products, which may be diluted heavily with water, the make-up of most sanitizers is primarily raw chlorine. Even most algaecides are 40- to 50 percent active.

As such, raw materials pricing weighs heavily into the operating costs of a manufacturer.

“The most important thing in our industry is material costs,” says Charlie Schobel, BioLab’s vice president and general manager, pool and spa products.

The largest determinant of raw materials pricing for pool chemicals is the chlor-alkalai market, which has been in a state of flux for some time. Plants that produce chlorine also product alkalai, or caustic soda, and the two don’t necessarily find the same kind of buyers.

“Unfortunately those two markets don’t always move together,” explains Joel Lindhal, director of chlor-alkalai and vinyls studies for Chemical Market Associates Inc. in Houston. “The timing being off by just six months means havoc on prices.”

Disparity in demand means chlor-alkalai plants have to balance operating rates in between producing too much of one material and not enough of the other, driving up the price of whatever is in the most demand.

While caustic soda prices were most recently affected, nearly tripling by summer 2008, demand on chlorine drove prices up in 2007. But it wasn’t until last summer that manufacturers were able to pass those costs onto the rest of the marketplace.

“Some companies like us have contracts, so those contracts keep us from having the fluctuations,” Schobel says. “Now that sometimes works in your favor and sometimes works against your favor.”

Contracts also held back price increases on trichlor and dichlor products until last year, which would have otherwise increased in 2007. These were generally due to increases in materials like urea and chlorine that go into cyanuric acid.

Meanwhile, inflation hasn’t helped those companies that use international suppliers. “A lot of the goods are imported, so they went up in price, mainly because the dollar was so weak,” notes Irwin Brown, vice president at United Chemical Corp. in Piru, Calif.

The future for raw material costs is uncertain. More recently, the demand for chlorine has been on the rise. By the beginning of 2009, industries that used caustic soda — pulp and paper, automotive, etc. — started to really fade, and manufacturers again adjusted their rates. Now that chlor-alkalai plants are swimming in caustic soda, they can’t raise chlorine production enough to meet demand.

“It looks like for another year or so, we’re going to be long on caustic soda… and there will be upward pressure on chlorine prices into 2010,” Lindhal says.

With operating rates crippling manufacturers that are already faced with weaker demand, don’t expect any price relief coming via raw material costs.

Of course, manufacturers are also footing the bill for whichever containers are used to carry these chemicals. Packaging, like everything else, has gone up, though it has had less of an impact than rises in chlorine and isocyanurates.

Although a lesser consideration than raw material costs, packaging is nonetheless influenced by fluctuations in the commodities market. Consider that the primary raw material that goes into packaging is polyethylene, which is used to make both soft plastic bags and rigid 5-gallon buckets.

“If you rewind and look at the prices for those raw materials a year ago, they were on the verge of reaching their all-time historical high,” explains Howard Rappaport, who studies the plastics and polymer markets for CMA.

Naturally, the increases made packaging more expensive, and manufacturers have been forking out more dollars for 3- and 5-gallon buckets over the last few years. And even as fuel costs have come down, it may take awhile for the plastics industry to pass on any price breaks.

Among the most obvious and direct changes that affected chemical manufacturers — as well as service companies, homeowners and just about everyone else — were gas and transportation costs. Naturally, freight costs went up too.

“Transportation costs are up, so it costs more to bring the product in,” Brown says. “The product manufacturers have to get that back somewhere.”

While rates were generally stable, carriers introduced fuel surcharges to combat high gas prices. These surcharges combined with a rise in packaging and raw material costs in 2008.

Furthermore, gas typically climbs in the summer because of the increase in travel — inconvenient timing for an industry that peaks in the sunny season.

Of course, the average price of on-highway diesel fuel has fallen almost 50 percent from last summer. But as transportation has less of an impact than raw material and packaging costs, the greater effect isn’t seen in pool chemical pricing.