Fowler is the commercial marketing and sales manager for Pentair Aquatic Systems in Sanford, N.C. He has been with Pentair since 1992, starting his career in the technical services department at Purex Pool Products.

Correct pump selection and optimal flow rates are extremely important to ensure proper flow and avoid “dead spots” in pools. This is especially true in today’s vessels that often have curves, grottos and vanishing edges. Pool professionals can also increase the energy savings with properly sized pumps. This article focuses on how to choose the right pump for different pools.

Sizing

Affinity laws indicate the power demanded by a pump is proportional to the cube of the flow rate. For example, if the pump’s flow rate is doubled, then its power demand is increased by a factor of eight. Therefore, it is important to utilize the smallest pump that is capable of completely turning over the pool water in an acceptable amount of time.

Furthermore, during the pump selection phase, the facility’s auxiliary features (e.g. spray pads and waterfalls) should also be considered, as it is common for them to use the pool’s main pump. Some building codes, however, require the use of a multi-speed pump, or a separate pump for each auxiliary pool load. Pumps on many pools are consciously oversized, sometimes more than 40 percent bigger than necessary. This happens because many architects and engineers look at what’s required, then pick the next size up to be sure the pump can handle the job.

Pump selection tips:

1. Determine flow rate in gallons per minute.

2. Calculate total dynamic head to account for friction loss. Adding 20 feet of head for a dirty filter is optional.

3. Refer to the pump’s performance curve to select the preferred unit.

4. Locate the required horsepower of the pump by plotting GPM vs. TDH (if plotted point falls between two pump sizes, select the next larger pump size).

5. Do not oversize the pump. Choose the best pump for the flow rate requirements (in other words, do not install a 20-hp pump where a 10-hp pump will suffice). If the preferred pump does not provide a proper fit, consider a different model.

6. Verify the selected filter can handle the system’s flow rate and be sure the minimum backwash flow rates can be achieved.

Avoiding dead zones

There are two solid ways to make sure a swimming pool is designed and circulated to eliminate dead zones.

Properly balanced plumbing: A hydraulically sound plumbing layout throughout the both the suction and return sides of the system is one of . Taking larger pipe sizes and breaking them down to smaller sizes in a balanced way around the pool will ensure that you have proper circulation and don’t leave any dead spots.

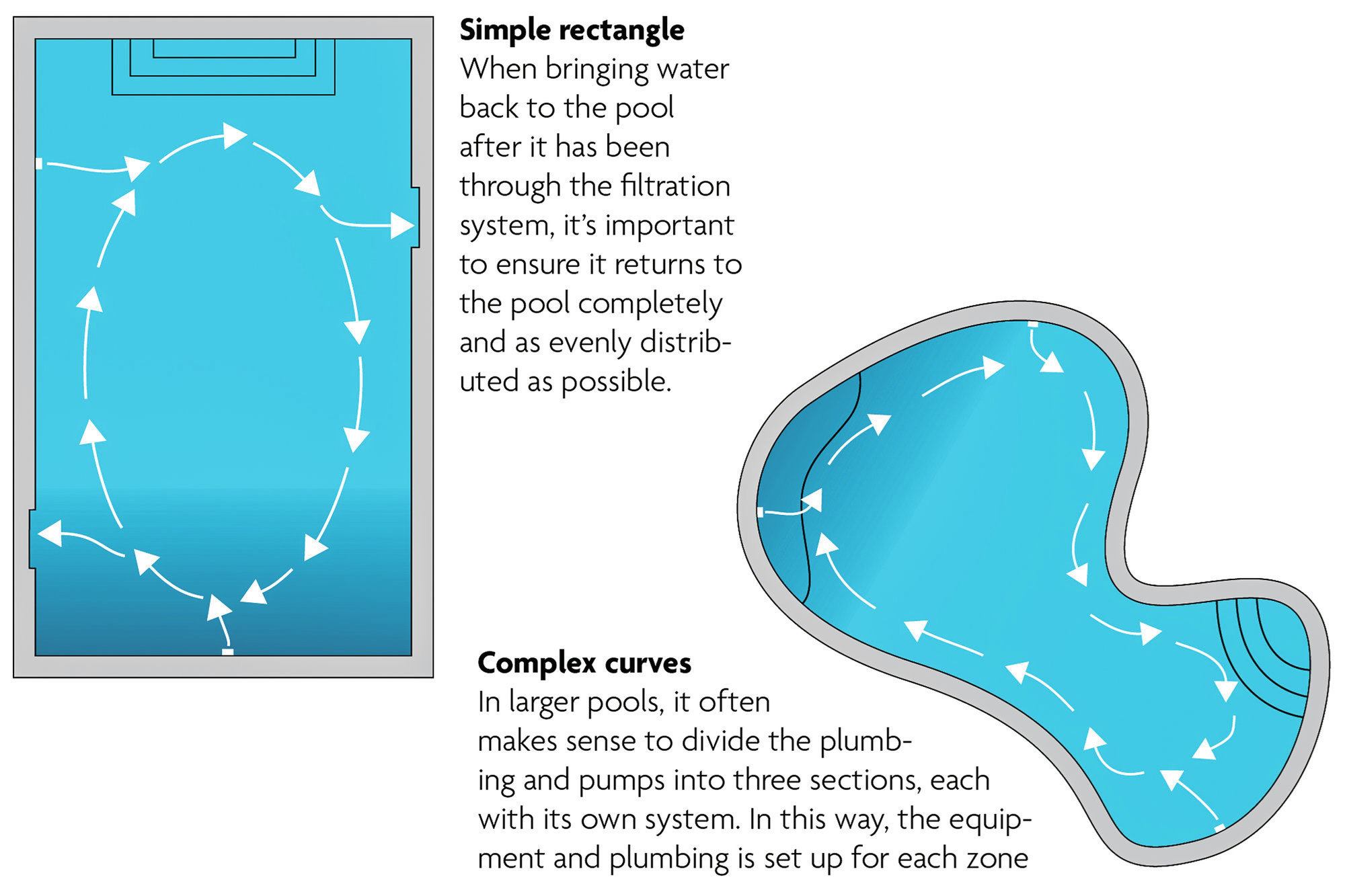

Proper placement and directions of return lines: When bringing water back to the pool after it passes through the filtration system, make sure it goes back to the pool completely and as evenly distributed as possible. Many contractors today will set up the return lines so the water is returned in a circular motion around the pool and also passes by skimmers in a strategic fashion to aid in cleaning the surface, as well as distributing the water. One suggestion is to cap the end of the return-line plumbing to increase the performance of those returns that are furthest away in your plumbing layout. This will ensure that all areas get proper circulation.

In larger pools, it often makes sense to divide the plumbing and pumps into three sections, each with their own pump system. In this way, each area of the pool is its own “zone” and the equipment and plumbing is set up for each. For example, say you have a 20-by-40-foot pool that has a grotto with a cascading water fall and a slide with its own water system in the deep end and a sundeck with a fountain and play area in the shallow end. You would divide the shallow end into one zone, the midsection of 15-plus feet into a second zone, and the deep-end area, or last 15 feet, into a third zone with pumps and plumbing sized accordingly.

Speed

Historically, pool pumps that operate at only one or two speeds have drawn more energy than is required to circulate pool water. Conversely, variable speed pumps can be programmed to operate at set speeds to deliver the correct flow rate for each task they perform. This allows a reduction in energy consumption and operating costs. VSPs can also be programmed to achieve turnover times of exactly six hours, even if the filter is dirty. This allows energy to be reduced during times when the filters are clean.

Some VSPs have built-in constant-flow software that allows the unit to automatically adjust its speed to deliver the required flow rate for each programmed task. For instance, if a laminar waterfeature requires 40 gpm to produce a smooth 6-foot arc of water, the pump will automatically ramp up its speed when it senses resistance in the circulation system (for example, as the filter accumulates dirt) to continually provide the proper flow rate.