Most pool professionals can tell you how ozone stacks up against traditional sanitizers such as chlorine and bromine.

But many don’t know how to properly operate and maintain the ozonator on a residential pool.

“It’s tricky because there are a lot of different systems out there,” says R.J. Marozzi, owner of Gourmet Water Systems in Westlake Village, Calif. “The pool guy walks in and thinks, ‘What am I supposed to do with this thing?’”

Ozonators produce ozone either through ultraviolet light or corona discharge. Each unit may have a distinct set of manufacturer recommendations for plumbing and maintenance.

When servicing an ozonator, it’s important to first orient yourself to the system, its installation and basic features. Though upkeep is minimal, routine maintenance is key to preserving the life of the unit. Finally, make sure the water is balanced for the ideal application of ozone.

Learn the system

When it comes to ozone systems, a technician must be able to recognize a correct installation and know the expected output for each pool.

If servicing a pool with an ozonator, start by consulting the unit’s manufacturer about its specific features and operation. You’ll also need to know the unit’s on/off procedures, particularly when it comes time to winterize the pool.

Begin by inspecting a few common problem areas.

The heater: Check to make sure the ozonator and heater were not plumbed in direct succession. If an ozonator is installed just before the heater, the ozone may oxidize and damage the copper heat exchanger. Conversely, by placing the heater just prior to the ozonator, there’s a risk that the hotter water will slow down ozone oxidation.

Back pressure: This can push water into the unit and severely damage the ozonator. A check valve generally will prevent water from backing up into the equipment.

However, because check valves wear out over time, it’s a good idea to take extra protective measures. Back pressure can be reduced by using larger eyeball fittings on the return line, assuming the ozonator doesn’t have a separate return. You also may reduce the number of fittings.

Power: If done incorrectly, simply turning the system on or off can damage the unit. On return-side ozonators with a venturi injector, for instance, running the ozonator without the pump on can cause major damage to the unit.

Chad Relis, service manager at Clearwater Tech in San Luis Obispo, Calif., says it’s vital to disconnect the ozonator during winterization.

“If the pool is winterized and you shut everything down, but still run water through [the system] so it doesn’t freeze, you’ll kill [the unit] if you don’t disconnect the tubing,” he explains.

Ozone output: It’s important to understand how much ozone a pool requires, and for how long. While the unit produces a certain amount of ozone, a ball valve at the injector will determine the rate at which it’s introduced to the water. A corresponding gauge on the unit tells how much ozone is being delivered to the pool.

As such, always keep the filter clean. As pressure builds, the amount of suction will change, altering the ozone output. If you don’t clean the filter, eventually there won’t be sufficient oxidation to clean the pool.

Maintenance

Often, a service tech will pick up an account with an ozonator already properly installed. The tech now must replace worn parts and ensure the unit works correctly.

The manufacturer will have a short list of maintenance procedures, but in general, keep an eye on fan screens, high-wear parts and bulb/electrode replacement.

Fans: An ozonator unit often has a fan to cool the unit and prevent it from overheating. If the ozonator you’re servicing has a fan, check for a screen or filter, which can become clogged with dirt and debris and must be cleaned.

“It’s actually the most important thing guys can do because [otherwise the units] overheat and can’t get air to cool them, so we get circuitry problems,” Marozzi says.

Screens can be cleaned and rinsed in the pool; then they should be set out to dry for three to four minutes.

Screens should be checked on a monthly basis, Marozzi adds.

Parts replacement: Higher-wear parts should be replaced every year or so. For some units, this could mean changing out O-rings or desiccant cartridges. Check with the manufacturer for recommended

replacements.

More generally, most ozonators should be outfitted with new tubing and check valves each year.

On outdoor installations, the unit’s clear vinyl tubing is constantly exposed to the sun. The tubing then will degrade, becoming yellow and brittle, and eventually crack. Though a vacuum system should prevent gas leaks, the ozone won’t be able to enter the circulation system.

Check valves may deteriorate as well; they should be replaced, along with the tubing, each year.

Electrode or bulb life: Corona discharge electrodes and UV bulbs are rated for a certain number of hours. CD electrodes generally last longer than UV bulbs, but both should last several years, varying by manufacturer and daily use. UV bulbs, however, will have a diminished effect over time.

Replacement is relatively painless and shouldn’t take more than a few minutes, according to Rick Taylor, a sales manager at San Luis Obispo, Calif. based DEL Ozone. Just be sure not to touch the UV bulb with your fingers because it could affect performance. As always, consult the manufacturer for replacement parts and recommended installation.

Warning signs: Many ozonator units include indicator lights that display current operating status and report ozone leaks. But a seasoned tech can detect other problems simply by observing the unit.

“There are certain sounds to listen for when something is wrong — like if a fan’s going out, the bearings will become loud and make funny noises,” Marozzi says.

For example, on a larger unit for a commercial pool, a broken oxygen concentrator will make a loud, continuous popping noise from inside the unit, he adds.

Correct water chemistry

A pool with an ozonator must be properly balanced. Industry-recommended levels for pH and total alkalinity should be observed.

But there are a few more things to watch for. Chlorine is now a supplemental oxidizer and should be introduced in smaller doses. Also, high TDS and hardness levels must be monitored because they can clog the injector.

Chlorine levels: Typically, chlorine is used as a residual sanitizer. Because ozone quickly leaves the main body of water, chlorine remains to fight any newly introduced contaminants. It’s particularly useful in oxidizing material that’s stuck to the pool wall.

However, maintaining 2- to 3 ppm of chlorine in the pool can be wasteful. The higher the chlorine level, the more likely that ozone will transform the chlorine to ineffective chloride ions. Instead, Relis recommends keeping between a 0.5- and 1 ppm level of chlorine to avoid complications.

Similarly, in-line chlorinators and ozonators can work against one another. The two systems should be kept separate and introduced at different stages in the circulation system.

Keep the injector clean. A venturi injector won’t get clogged in a pool with good water chemistry, provided the ozonator is correctly installed after the filter.

However, high levels of calcium can cause buildup where the ozone and water come together inside the injector.

This reduces ozone output — and may prevent the pool from effectively oxidizing contaminants. You can test for poor vacuum draw with a flow meter where the tubing connects to the ozonator unit. If the draw is poor and there’s no obstruction in the tubing, there’s probably buildup.

If the injector becomes clogged, some manufacturers recommend disconnecting the tubing and injector from the unit, and cleaning them with vinegar or a muriatic acid solution.

Soaking the tubing and injector for a few hours should clear out any mineral deposits.

If there’s a high hardness level, a chelating agent can help prevent material buildup.

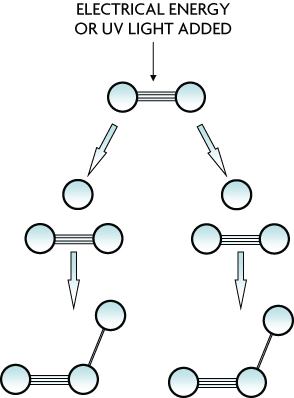

Oxygen molecules (O2) split by adding energy or UV light, resulting in two individual oxygen atoms (O1).

Oxygen atoms (O1) unite with other oxygen molecules (O2) to produce ozone (O3).

(O1) + (O2) = (O3)