Energy efficiency is talked about in all parts of our lives, from the cars we drive to the refrigerators in our kitchens. The swimming pool is no exception.

It is my guess that everyone reading this has had at least one conversation with customers in the past year regarding energy efficiency or reducing energy costs. Some of these discussions may have been driven by a desire to save money, because you were explaining the benefit of upgrading a piece of equipment on the pool pad to a new technology, or by municipal or regulation requirements to reduce stress on the electrical grid. Whatever the reason,we can all agree that we need to play our parts to ensure that we provide the highest level of service so customers gain satisfaction from their pool while enjoying a reduction in energy consumption over time.

It’s widely acknowledged that pool builders and equipment manufacturers aim to ensure optimal efficiency for new pools. But when you take into account the more than 5 million pools already installed in the U.S., attention shifts to pool service companies and remodelers. In this case, while many of the hydraulic efficiencies are quite literally set in stone, there are still things that pool technicians can do to optimize the energy efficiency of the swimming pool equipment pad for existing pools.

1. Fix inefficient plumbing. We’ve all been to those jobsites where, after years of different service companies and people replacing equipment of different shapes and sizes, the pool pad can become a monster of elbows and piping above ground. In these cases, sometimes the best thing to do is just cut the plumbing back to the pipes coming out of the ground, and replace all the plumbing on the pool pad. Eliminating turns in piping is a great way to increase hydraulic and energy efficiency. Also, switching to standard 90-degree elbows with sweep elbows, which are about 60% less restrictive, can have a major impact, as can more optimal pump selection or the ability to run a variable-speed pump at a lower speed.

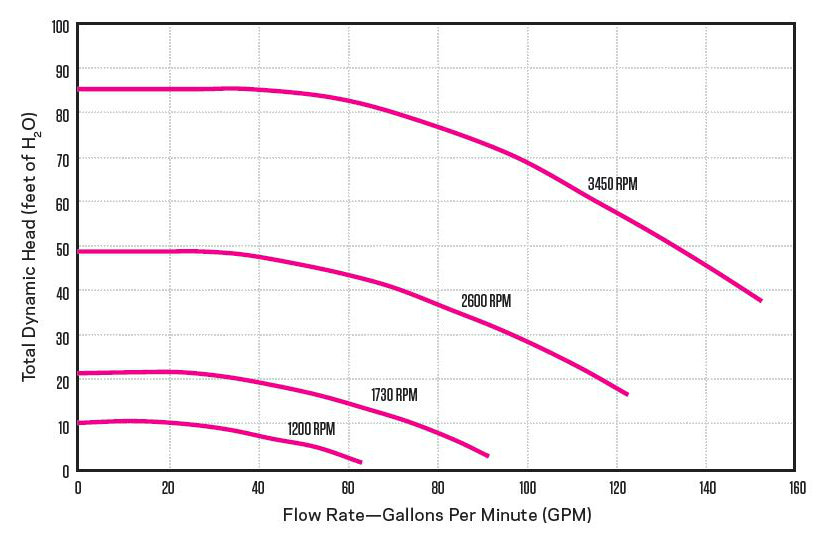

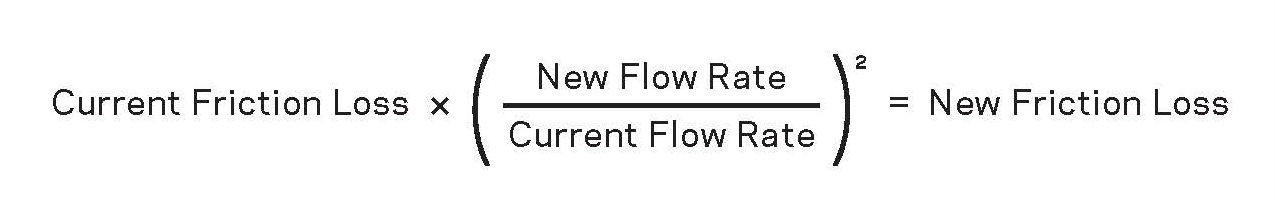

2. Size the pump properly. Knowing what you are working with underground is a huge advantage in properly sizing and setting up filtration pumps. Most pumps are set up with pressure ports on the suction and pressure sides of the pump. To size a pump, use a vacuum gauge on the suction side and a pressure gauge on the pressure side. Run the pump at full prime and RPMs and record each measurement. Watch out for units of measure — most pump curves are in feet of head (ftH₂0). So if your suction (vacuum) gauge is measuring inches of mercury (inHg), multiply by 1.13 to get ftH₂0. If the pressure gauge is in pounds per square inch (psi), multiply by 2.31 to find the ftH₂0. Now add these two numbers together to give you the total dynamic head for that flow rate. Then use this formula to calculate the new friction loss at different flow rates:

3. Install a variable-speed pump. This is likely the No. 1 way that servicers can offer the most significant reduction in energy consumption. Typically, the upfront cost of a variable-speed pumps poses the largest roadblock to convincing a pool owner to make the switch. While this is a real cost, we often find that the pump will pay for itself many times over its life.

When discussing this with customers, think of the pump in a context that is easier for them to understand, such as light bulb efficiency. For example, if pool owners run their filtration pump during the day, have them think of a single-speed pump as equivalent to 16 light bulbs that are on for 8 hours a day. In this scenario, a variable-speed pump running at a lower speed could be the equivalent of two to four light bulbs, and even if they need to run it longer than eight hours per day, it still won’t consume anywhere near the electricity of a single-speed pump.

4. Replace old, less-efficient equipment. The electrical efficiency of electronic pool equipment is constantly moving forward. While regular maintenance can prolong performance, equipment will never be more efficient than the day it was installed. Pump motors are being designed to be more energy efficient, gas heaters, which used to be 76% thermally efficient are now at least 82% efficient, meaning that less gas is needed to result in the same amount of heat rise.

5. Use more hydraulically efficient equipment. New equipment is also getting more hydraulically efficient with each release. The increased focus on efficiency is driving pool equipment manufacturers to develop products that are more hydraulically efficient, employing such tactics as updating heater and filter designs to have lower friction losses. There are also more recent designs that allow bypassing of water around equipment when it’s not in use. Looking for equipment that has these features built in will be critical to providing the most energy-efficient pool pad for your customers.