STEVE BARNES

Pool and spa professionals are becoming more proficient at creating energy-efficient plumbing systems.

“Within the past 10 years, I’ve seen a marked improvement in the industry as far as people wanting to do better plumbing,” says Dan Johnson, owner of Swim Inc. in Sarasota, Fla. “This year I’m teaching at the Southwest show, the Florida show and the International show, and it’s all about hydraulics. It’s in big demand.”

However, there are still some fairly common missed opportunities for energy savings when it comes to the equipment pad. Here, experts discuss them.

Filter: Improper operation

The question of energy efficiency has introduced something of a wrinkle when it comes to the choice and size of filters.

Conventional wisdom has said that filters should be run a little dirty because the extra grime tightens the gaps in the media so it can sift smaller particulate than when the unit is pristine. This was always considered a happy coincidence, since it also meant longer time spans between backwashings of sand and DE filters, as well as cartridge changes.

However, a dirty filter also adds pressure to the circulation system, which causes the pump to work harder and use more energy.

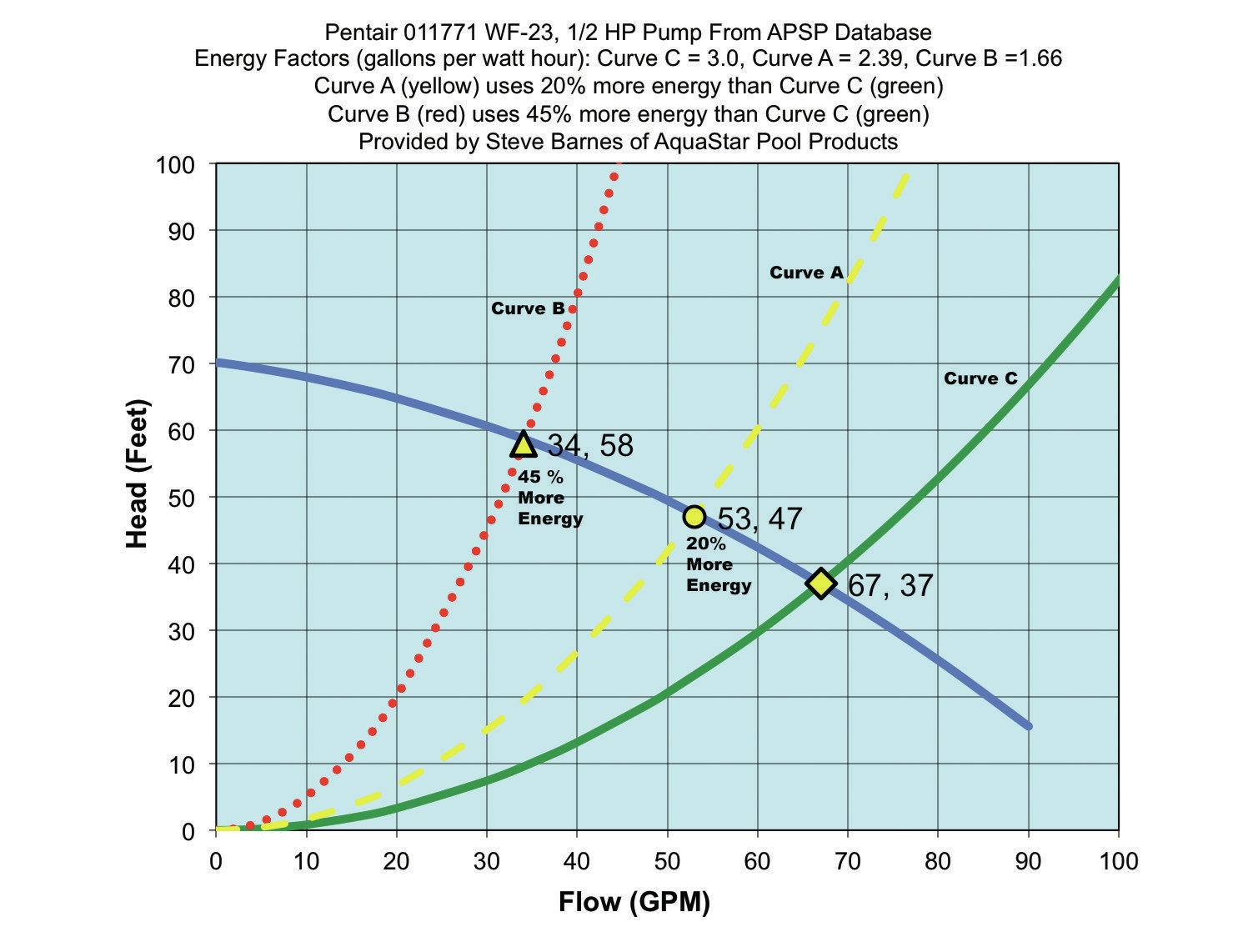

“Instead of saying, ‘Backwash your filter when it reaches 10 psi or 15 psi,’ it’s better from an operational standpoint to build into the system convenience so they can backwash more frequently at approximately 2 psi,” says Steve Barnes, director of science and compliance with AquaStar Pool Products in San Diego.

This will prevent the filter from becoming filled with debris, making it easier to clean. In addition, keeping the back pressure down means the pump doesn’t have to work as hard, and the pool will be cleaner with a lot less energy, Barnes adds.

As far as the quality of filtration, the good news is that, with a variable-speed pump running at low speed, even sand filters are better able to capture smaller particles than on high speeds, since the particles are not being forced through the media at high pressures.

Heater: Failure to bypass

The heater presents another potential for added resistance in the system. For this reason, installers should consider bypassing the heater so that water only runs through this component when warmth is needed.

“Bypassing the heater creates an opportunity to reduce head loss,” says Jeff Farlow, program manager of energy initiatives with Pentair Aquatic Systems in Sanford, N.C.

This is especially important on systems where the water is running at a higher speed, such as pools without a VSP. When flow rates are very slow, the impact of a heater is reduced significantly.

Automatic sanitizer: Wrong choice, failure to bypass

Not all chemical feeders and sanitizers are created alike. Some cause more restriction to a system than others. While it’s hard to say that a feeder or sanitizer should be chosen solely for its energy-saving potential, pool and spa professionals should explore this issue with each option and discuss it with clients before they make a decision.

In addition, chemical feeders, ozonators and salt chlorine generators often do not require the system’s entire flow to pass through them in order to effectively sanitize the water. For instance, some may only require and accommodate 50 gallons per minute of flow, while the system pushes 100 gpm. If the feeder or sanitizer adds feet of head to the system, then it will eat unnecessary energy to push more-than-needed water flow through it. For this reason, part of the flow should be bypassed around the feeder or sanitizer. Only send as much water as is needed.

Automation: Not using it to its full potential

Using LED lights over standard bulbs will save energy, and variable-speed pumps certainly have that potential as well. However, the potential isn’t met if the equipment runs longer than it should, if the pump works on high speed unnecessarily or the lights turn on before it’s dark outside.

When it comes to the variable-speed pump, there should be separate modes for simple circulation versus cycles that require higher volumes, such as running automatic pool cleaners or spa jets, or activating waterfeatures and vanishing edges. For circulation, move the water at the lowest speed. When it comes to cleaning mode, try to keep the time as short as possible, since it will require additional energy usage.

“I set one speed to schedule and then I leave them four speeds for when we’re not there,” says Tom Cucinotta, owner of Cucinotta’s Pool Service Inc. in Lake Worth, Fla. “If they want to run their vacuum to give it a little bit of a boost, I’ll set Speed 3 for vacuum mode. Speed 2 might be just to skim the surface. Speed 1 might be because they’re running a waterfall, and Speed 4 could be for when they go to heat the pool.”

If the system isn’t easy for the homeowner to run, that could throw everything out the window. For this reason, professionals recommend programming the equipment in various modes to adapt to the particular use. A “party mode” could set up the water at maximum movement and lights at their brightest for when customers entertain.

But don’t stop at simply the programming itself, Barnes says. Be sure to present the homeowner and, if possible, the service technician with an operational plan so they know how long the pump should run at high speeds and how long at low.

Pump: Starting at wrong speeds, placing units higher than the pool water

Energy efficient pumps allow professionals to customize the system so it works on high speeds only when necessary and remains at low speeds whenever possible. When basic circulation is performed at low speeds, it saves energy, even though it takes longer for proper turnover.

The performance of the pumps can be improved by avoiding the mistakes outlined below.

In addition, installers should reverse a notion that has traditionally been held, at least in the Florida market where Johnson works. Many builders believe that pumps should be set up to kick on at high speed, run that way for a while, then slow down, Johnson says.

This may be based on how things were done in the past.

“Manufacturers of those pumps were programming them so when you put the pump in, it automatically started on high speed,” Johnson says. “When they first came out, they just built them that way.”

But today, there really is no need to do that in most cases, the builder says. Installers should just program the pump to start at the speed it ultimately needs to run for the function it’s about to perform.

The most common exception would be if the pump is set more than 2 feet higher or lower than the rest of the system, or if it needs to feed water through a solar system placed on the roof. Such elevation differences should be avoided if possible for maximum efficiency.

Plumbing: Failure to plan and specify

It’s true that the pump itself has the most potential to use up wattage. But in addition to choice of the pump and other equipment, a key part of minimizing their energy consumption is in the plumbing. This includes the plumbing on the equipment pad.

Unfortunately, too many builders leave it up to their plumbing subcontractors to determine the size and placement of the lines and elbows that can add unneeded resistance in the hydraulic system, experts say. If the sub isn’t well versed in energy-saving plumbing, that defeats the purpose.

“That’s a huge missed opportunity,” Barnes says. “Every extra elbow and fitting is adding 5 to 10 feet of equivalent pipe. Spending an extra hour or two in defining exactly where and how they want to run so they can eliminate extra fittings has a huge impact on energy efficiency.”

Instead, pool designers should take some extra time to lay out a schematic for the subs. It may even pay off for an installer to go so far as to provide CAD drawings to the subcontractors. That’s what Johnson did, until his plumber became well versed in efficient plumbing.

“When I hired the plumber I currently use, I worked to get him to understand why I do what I do, and I would go over every layout,” says Johnson. “Now he understands almost as much about fluid dynamics as we do.”

From tornado to clothes dryer

For the past few years, experts have discussed the role of the pool inlet placement in reducing energy usage. Since one key to saving energy is running the system for as short a time as possible, the water should be moved in the most effective manner insider the pool, so it can be filtered quickly and efficiently.

Steve Barnes, director of science and compliance with AquaStar Pool Products in San Diego, offers a helpful mental image to illustrate the concept. The traditional jet placement moves water around the pool in a big circle, like a tornado. Experts now are finding that a more effective means moves the water like clothes in a dryer, with the water tumbling in a circle that traverses the depth of the pool, rather than its perimeter.

“If you do it in a circle, all the bugs, debris and filth will move to the center of the circle, and almost never will that align with the drain,” Barnes says. “Instead, we want to aim returns downward to the floor of the pool on one side, so the water begins to move in a giant circle, like a giant drum or clothes dryer. The water goes across the floor of the pool, which keeps it clean and fresh relative to algae growing and dirt not settling. Then the water goes up the far side of the pool, and that drives surface debris to the skimmer — if it’s on the same side as the returns.”

Besides aiding in the skimming and cleaning, this set-up also better moves the heated water to help maintain a more consistent temperature at any depth.