Inspiration often comes in surprising ways.

For instance, I never thought that watching National Lampoon’s Christmas Vacation would result in a new business approach. The movie premise centers around Clark Griswold, a man who imagines his dream backyard pool while eagerly anticipating his annual bonus.

While tuning in to the cult classic movie, I noticed Clark Griswold holding a crude, simplistic model of a rectangular pool with a rigid diving board. While Griswold’s simple swimming pool hardly qualified as great design, I thought that most homeowners could relate to the character’s struggle to imagine the possibilities for his dream pool. I thought perhaps they, too, would like a model of their own to help them visualize their dream project.

I wondered why I couldn’t do the same thing to help my clients. I figured that a 3-D print — a tangible representation — was just what clients needed to build excitement and help them visualize their pools and landscaping.

In its short history after being developed in the early 1980s, 3-D printing has been gaining in popularity. Today, it is being used in virtually every field, including the apparel, automobile, construction, medical, space, and food industries.

Essentially, 3-D printing is an additive manufacturing process that produces a three-dimensional object. And while this technology isn’t widely available to the general public yet, it is likely that 3-D printers soon will be a standard household item.

The technology was quick to catch on among architects, who have created 3-D prints of home designs for some time. They embraced the trend as a smarter, quicker replacement for time-consuming hand-built models. With the 3-D printer, models are faster to build, lighter and sturdier, and multiple copies can easily be made.

And, during the design development process, 3-D models can help identify pitfalls that have been missed. But most importantly, clients can see just how the building itself fits with its surroundings.

The landscape architecture industry has been slower to adopt this technology. 3-D models of organic landscapes can be much more challenging to create compared to right-angled cityscapes and buildings. The process is complicated by the unpredictability of a backyard, the synthesis of nature’s creation and our retooling. Grade changes and other outdoor elements can be difficult to represent accurately.

But we try to utilize the latest technology when designing pools and spas for our high-end clients, so we began using printed models as a design tool in early 2015, and it has been beneficial to both designers and clients. In that time, I’ve found that the long list of benefits heavily outweigh the short list of challenges.

Clients have a hard time visualizing their future projects, but seeing is believing with a 3-D model: They can view the designs from all possible vantagepoints for a more complete picture. The models also provide a memento for clients to keep during the lengthy construction process. It helps sustain enthusiasm, especially when we have to interrupt construction to allow certain stages of the home to be completed.

Not only do we receive positive feedback from clients, but the prints further help us further understand elevations and connections between the elements in the yard. We might look at it and say, “Let’s raise this; let’s make an adjustment here.”

The models have been so warmly received that we intend to use 3-D printing for every future project. Of course, homeowners and architects can look at the project in 3-D drawings or animation, but you’re still looking at a two-dimensional plane — the paper or computer screen.

However, there is a learning curve, so it took us probably three months to understand the 3-D printer. We have designed with SketchUp software for several years, and we can use that to produce 3-D prints. But you have to relearn how to use the software if it’s going to be a 3-D print — there are certain ways you have to close out the solids so the computer will recognize it.

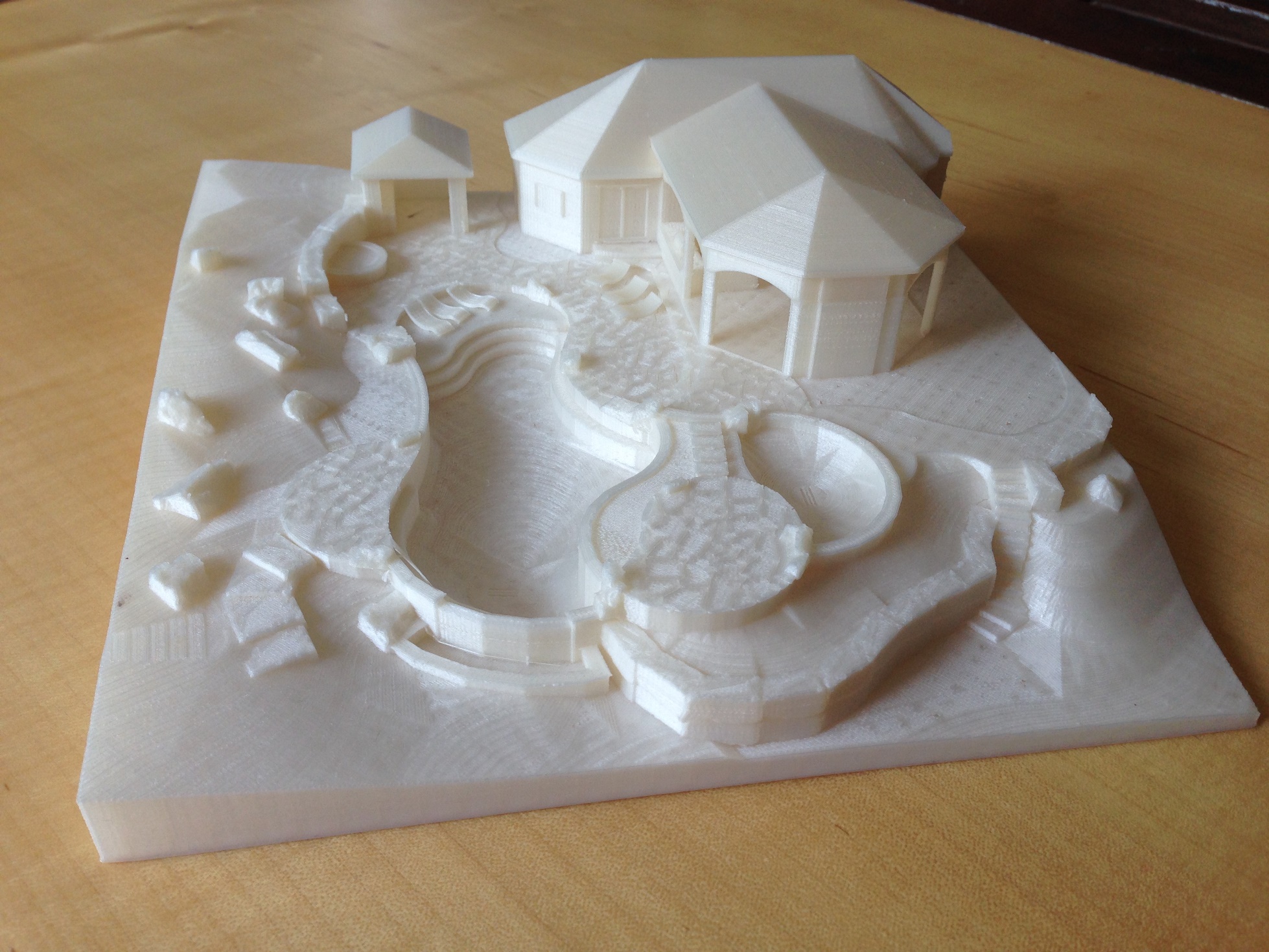

Once we were used to the software and 3-D printer, we tackled our first 3-D model. It included the adjacent architecture, pool, surrounding deck and other amenities. We generally include the back portion of the home in the print. We want to make sure that our design fits contextually with the home as intended by the architect, and we are studying the scale and proportion of the model. We will build the entire home if it’s an extensive project with several features all around the property.

As we’ve refined our skills, we’ve been able to produce more intricately detailed 3-D prints. Our initial designs were fairly simple — we would just include the pool and decks. The surfaces would be flat and smooth, even if the real-life version was to be finished with a textured material such as flagstone. Eventually we took a bolder approach to the detailing. On a project we built two years ago, for instance, we we printed the pool deck to delineate the flagstone, so you can see the pattern. Then we began creating boulders, and now we have small furniture models that we print independently and glue onto the model. We also print components such as fire pits, pergola structures and shade canopies.

On a recent project, the pump pad was within the overall footprint that we wanted for the model. We thought, “Why don’t we just go ahead and build the pump pad?” We created all the components — valves, filters, contact tanks for the ozone system. When we showed this to a colleague, that was the first thing she noticed. She said she would like to provide a 3-D printout of the pad to crews in the field so they can understand the configuration.

Right now we’re building the models in what I call museum quality, all in a creamy white, so it looks like a sculpture. Occassionally, we’ll put colored water in the pools, and we are preparing to experiment with painting the models.

To be sure, creating the models this way requires a commitment. They generally take us 80- to 120 hours to build out.

Occassionally we create a couple iterations of the prints as the design process progresses. But since the prints require so much time, we try to limit it to one: We refine the pool design until it’s ready for final approval, then the components around the pool may change afterward.

In our first year using the 3-D printer, it’s gained momentum. In fact, we’ve talked about getting another printer and, at some point, perhaps hiring another staffer. And in the future, we may be able to send files to our clients so they can print the models right at their own desks.

I believe many people are very tactile — they like to touch and feel things. Perhaps Millenials will prefer to view designs through a digital format but, for now, many clients seem to connect with hand-drawn graphics and 3-D models. I’m willing to go that extra mile if it helps the client feel more comfortable and engaged.

Kraisinger is president of Lorax Design Group in Overland Park, Kan. He studied landscape architecture and planning at Kansas State University, and has more than 20 years of design experience.