Six months past the compliance deadline for the Virginia Graeme Baker Pool and Spa Safety Act, pool professionals are still learning the nuances of the law. Simply screwing down a newly compliant drain cover without considering a pool’s hydraulics may not be making the pool any safer. Similarly, incorrect installation of a safety vacuum release system can defeat the very purpose of the device.

And all too often, service techs lean on intuition and last-minute phone calls when installing an SVRS.

“It’s kind of like a dad with a bike at Christmas time — the last thing in the world he wants to do is to read the instructions,” says George Pellington, East Coast sales manager for Vac-Alert in Ft. Pierce, Fla.

The installation of SVRS devices is relatively simple. However, techs should be aware of some common mistakes and work-arounds that occur in the field. If the units are installed correctly, they should provide a vital layer of protection rather than a tripping nuisance.

Remember, most manufacturers provide installation support in the form of written instructions, DVD tutorials and online diagrams. This primer should always be secondary to a manufacturer’s recommendations.

Location, location, location

For the uninitiated, an SVRS is a vacuum-sensing device that either sends air to the pump and/or powers down the pump motor when it senses a vacuum increase.

“The [unit] acts like a mechanical vacuum breaker, just like you have a GFCI in your bathroom that protects the outlet,” Pellington explains.

Generally there are two types of SVRS devices: electrical and mechanical. The mechanical models send air to the pump so it will cavitate, thus releasing the vacuum. The electrical models do this as well, in addition to actually powering off the pump.

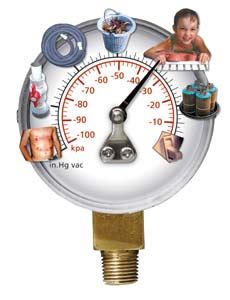

Choosing the SVRS is both a matter of preference and setup. Some units are designed to operate at certain vacuum levels, while others can be calibrated for greater range.

“The standard unit without the adjustability caters to your shorter pipe runs and lower-range vacuums,” says Mike Steffen, sales manager at Vac-less in Simi Valley, Calif.

Furthermore, certain units may be a better fit for certain vacuum levels. The higher vacuum pools often have larger pumps and more labyrinthine hydraulics. In some cases, the tech will be better served to downsize the pump. While most units have an adjustable vacuum reading, many SVRS manufacturers recommend a level under 18 inches of mercury.

Installations vary by maker. To minimize the vacuum and ensure accuracy, some manufacturers recommend installation on the main drain line only, without picking up vacuum from the skimmer.

“We discourage people from putting the Vac-Alert on common lines, because then it would be required that it be sensitive to all circuits, and it’s not as good an install,” Pellington says.

Although proximity to fittings is not a major issue, keeping the unit between 5 feet and 18 inches from the pump makes for the best install, he says.

Still, other units attach directly onto the pump.

“All you have to do is remove the suction-side drain plug,” Steffen notes. “We have a little extension elbow that we provide as an optional installation piece, but basically our unit is just hand-screwed into that plug.”

While mechanical units are physically plumbed into the hydraulics, electrical units require installers to drill a small hole in the suction-side plumbing, connecting a tube from the pipe to the SVRS.

“We tell people to tap it at 10 o’clock or 2 o’clock, because if you do it straight at 12 o’clock, if any air gets in there, it will go to the top of the pipe first,” says Russ Burke, district sales manager for Hayward Pool Products in Pomona, Calif.

Electrical units should also be properly grounded and bonded according to local codes.

Finally, you will need to calibrate the system. Make sure the filter is clean to ensure a standard vacuum level. For any pool with a higher vacuum rate, manual units will have to be adjusted to find the right setting.

“You turn the cap clockwise or counter-clockwise, which will basically compress or expand the spring tension to allow the piston to hit the air channels that are designed inside there,” Steffen explains.

Consult the manufacturer to ensure your vacuum level is within a workable range.

Tripping hazards

Nuisance tripping on SVRS systems often is the result of incorrect installation or poor maintenance. For units with an automatic restart, these trips may simply be an annoyance. But for any SVRS that requires a manual restart, nuisance trips on an untended pool can add up to very green water.

Many units are sensitive to the small changes in vacuum, and a swing of 3 inches in vacuum could trip the SVRS.

Check valves, for example, on the suction-side of the pump can drastically change vacuum levels.

“You cannot have a check valve on the suction side of the system — the fluttering of it could have it trip,” Burke says.

These valves should be taken out prior to installation.

Be aware that installing a new drain cover will also change the vacuum level. Unless the replacement cover has the exact same open surface area as the original cover, the pool will be operating at a different vacuum level. A large difference in open surface area could cause the unit to trip.

Although less common, poor maintenance could also cause nuisance tripping. An untended pool can build up its vacuum level with accumulating debris.

“The pump and the skimmer basket, especially…when the winds kick up, could cause a trip, but they would have to be pretty packed,” Burke notes.

Occasionally, something random can block the outlets, such as a towel on the main drain or a plastic bag in the skimmer, he adds. However, these are unavoidable consequences of a public pool.

Be aware that changes on the pressure side of the pump can affect the vacuum level as well.

“If the pump is pumping against a higher pressure and therefore at a lower flow, the vacuum level actually goes down,” Pellington explains.

Some units will trip with a drop in vacuum as well as an increase. This means a dirty filter, return-side blockage or an impacted pump impeller could cause problems. Techs should investigate these areas when diagnosing a false trip.

In operation

The successful operation of an SVRS also depends on proper testing and maintenance. When the installation is finished, the SVRS should be tested several times to ensure it will work when the pool experiences a vacuum drop. Techs can also use a pole-guided mat to move over the main drain, although that’s best for single main-drain applications.

Installing a ball valve just before the SVRS is also a popular option for testing. Turning the valve on should set off an instant change in vacuum and cause the unit to trip.

Choosing between the two may be a matter of preference.

“Some building officials like the mat test because they feel it better simulates a real entrapment event,” Pellington notes. “Others are quite happy with the valve because…they can test it.”

Furthermore, if the SVRS is installed on a residential application with a ball valve, the homeowner may even test it to ensure it’s operating properly. Most manufacturers recommend testing the unit on a monthly basis.

Maintaining the unit often is a matter of keeping a steady vacuum level and addressing any tripping.

If a trip does occur, depending on the model, SVRS units will either automatically reset after a given amount of time — often programmable with the electric units — or stay shut off until a service tech can manually reset it.

“Some people prefer that to make sure they’re able to resolve any incidents and have time or ability to reactivate the unit,” Steffen notes.

If the unit does require a manual reset, make sure a service technician is available, particularly in a commercial pool setting.

Also, make sure the line from the SVRS unit to the plumbing is clear. If there’s any kind of blockage in the tubing or on the vent screen, the unit will not be able to send air to the pump to prevent a suction entrapment.

MORE INFORMATION

- Maintenance Mode

Keeping the SVRS from tripping when doing maintenance.

RELATED LINKS

- Video: Drain Retrofit

Get a step-by-step look at a spa drain cover retrofit.