MORE INFORMATION

- Special Report: Covering the Drain

- Entrapment Testing at a Glance

- Road to a Recall

- Physical/Ultraviolet Testing

- On the List

These small pieces of plastic have recently generated huge headlines, but ensuring the safety of drain covers is much more complicated than the sound bites suggest.

Here is a short definition of each test and an explanation of the entrapment it is designed to stop.

A timeline of events that led to the drain cover recall.

Secure placement and ultraviolet exposure are two additional factors that must be addressed.

A list of the models named in CPSC’s recall.

A new version of the drain-cover standard, ANSI/APSP-16, is scheduled to be released later this year. It will address the issues that spurred the recall, as well as provide more explicit guidance to the testing laboratories.

However, some members of the writing committee are already looking toward fine-tuning the standard further after releasing the rewrite. Specifically, they hope to include language that would render the body-blocking element more representative of a human, including the addition of a material that behaves more similarly to skin under testing conditions.

Yet even while these modifications take place, some believe the standard’s basic approach is off-track, while others would like to see a completely different set of adjustments.

The first group contends that by devising more intricate tests and mandating specific equipment, the standard-writing committee is adding layers of complexity to a process that, if anything, should be simplified.

“They’re just clarifying ways to make a complicated test procedure more clear, but I think it’s really unnecessary,” says Brooks Hilton, general manager for Waterway Plastics, a pool and spa products manufacturer in Oxnard, Calif.

Hilton and others believe that most safety concerns could be satisfied if flow ratings were established to maintain a maximum velocity specified in the standard. As an example, Hilton cites the 1.5-feet-per-second limit in Florida and other areas.

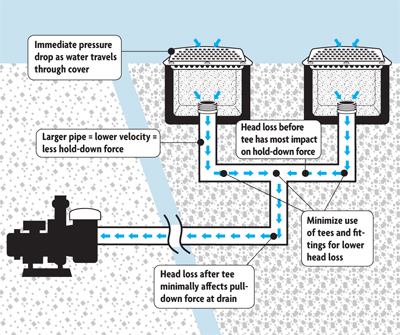

High water velocity is a significant contributor to suction entrapment since, in a closed, pressurized system, negative pressure, or suction, grows geometrically as the speed increases arithmetically. However, velocity is more difficult to establish than flow. Because of this, the literature provided by drain-cover manufacturers will state the highest allowable flow, along with the velocity achieved at that rate. In a hypothetical example, instructions could indicate that the drain cover is rated for 100 gallons per minute, which might produce a velocity of 4.5 feet per second.

If, instead, velocity was the guiding variable, the pull-down force could be made so weak that any potential for entrapment would be significantly reduced or eliminated.

Hilton, and others, also suspect this approach would aid in keeping the various parties honest. “You don’t have to do testing for [velocity],” he says. “You measure the open area and do a mathematical equation, and that’s how fast the water will come through it. There’s no testing, no fudging. [And] you don’t have to get this expensive, hard-to-find, hard-to-duplicate test.”

For this solution to be effective, however, it would have to be implemented in concert with additional guidance on such issues as sump dimensions, cover height and geometry, as well as requiring properly plumbed multiple-suction outlets for each pump.

On the other end of the spectrum are those who believe that more fine-tuning should be performed for the testing to better reflect the real world. One expert, for instance, would like to see additional changes in the body-blocking test. Bill Rowley, a designer and consultant who has studied entrapment for more than two decades, objects to the blocking element being pulled off the drain in one motion. In an actual entrapment, he says, the swimmer only needs to separate a portion of his or her skin from the cover to break the seal.

“If you or I got stuck on a drain, we don’t lift straight up,” says Rowley, president of Rowley International Inc. in Palos Verdes Estates, Calif., who has performed several mock entrapments on himself to study the phenomenon. “We reach out with our arm on one side or other and roll off it. It’s like peeling off a postage stamp. And the second that you… have a hole and flow going into it, the vacuum automatically releases.”

However, some on the standard-writing committee don’t agree that a person who’s been trapped, or those frantically trying to rescue them, would intuitively know this. Instead, they believe, victims reflexively try to pull off using their whole bodies.

Another detractor wants to see alterations to ratings for the hair test. His concern involves the so-called “safety factor” that has been part of the protocol for some time. To compensate for less-than-accurate readings, laboratories determine the maximum flow at which a hair entrapment hazard is avoided, then reduce that number by 25 percent. So if the cover tests safe at 100 gpm, it will be certified for 75 gpm.

Now that a more accurate and duplicable test has been developed, the standard should remove the safety factor entirely, says Ron Schroader, a former member of the standard committee and principal of manufacturer Drainsafe/New Water Solutions in Lake Worth, Fla. He expects the safety factor will unnecessarily reduce the rating of several drains.

“They’re going to de-rate the covers so much that they’re sacrificing a sanitation issue for a safety issue,” Schroader says. “Instead of being able to turn over a pool in, say, six hours, like the Department of Health requires, they’ll only be able to turn it over in maybe 7-1/2 or eight hours.”