In today’s economic environment, it’s easy to focus on purchasing the lowest-priced item available. But educating the consumer regarding the energy efficiency of variable-speed motors will provide savings the very first year after installation. These motors can use up to 90 percent less energy than single-speed units, and often pay for themselves within two years. They are designed to outlast single-speed motors, and also are much quieter. Here are some details that will help customers understand the benefits these motors can bring.

Efficiency

Variable-speed pool replacement motors are relatively new in the pump industry. This technology type, brushless permanent magnet (BPM) motor, utilizes a magnetic rotor instead of a squirrel cage rotor. BPM technology has seen rapid development in the past few years. These motors with an integrated variable frequency drive (VFD) can convert standard single phase AC power into a DC sine wave and vary the frequency of the motor. Varying the frequency varies the speed as well. The brushless design eliminates the need to transfer power to the spinning rotor and offers longer life spans, minimal maintenance and small size.

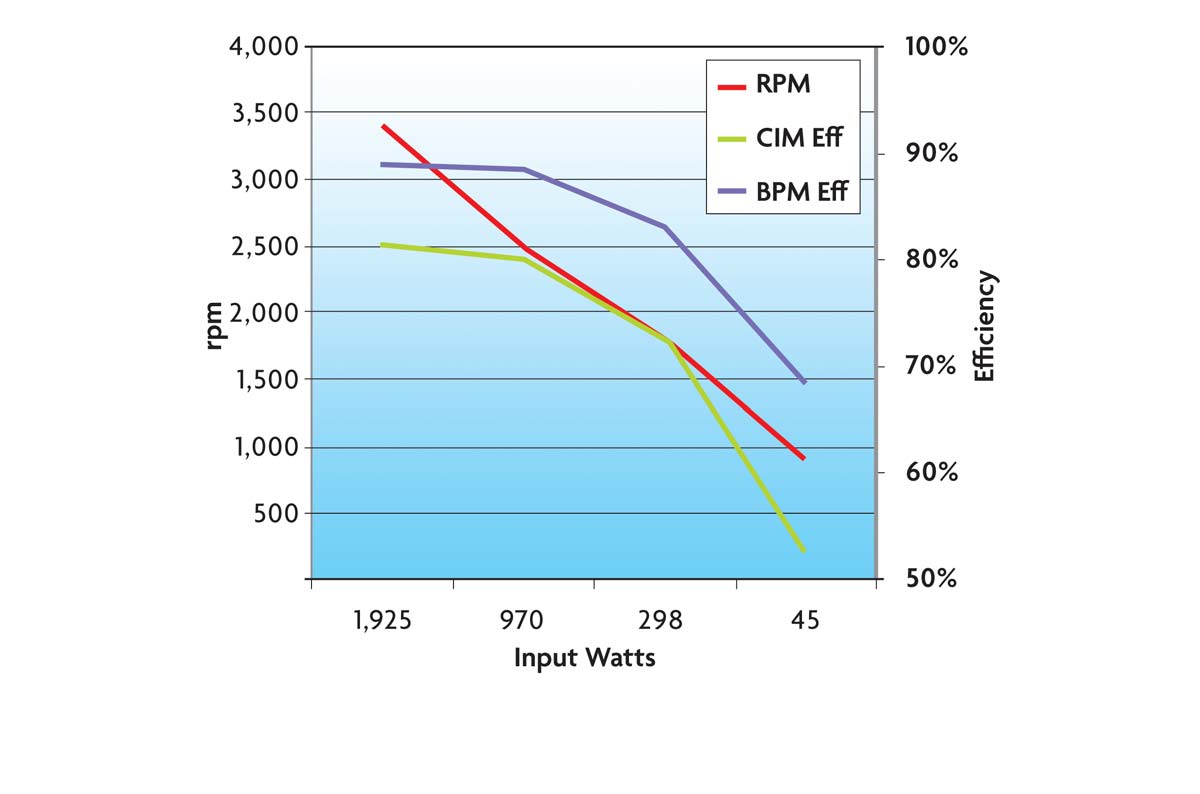

Here is an efficiency comparison chart comparing a standard three phase variable-speed motor vs. a BPM variable-speed motor being run on the same pool pump using the same VFD. The only difference in this test is the motor type. As the chart shows, BPM efficiency is significantly higher across the speed range.

The VFD on a variable-speed pool pump replacement motor also is key in determining the overall efficiency of the product. The VFD is generally sized to match the motor in terms of performance and requirements. The VFD is the component that allows the motor and pump to run at the slower speeds.

The laws of affinity

The affinity laws are used in hydraulics to express the mathematical relationship between the several variables such as head (pressure), volumetric flow rate, speed and power involved in pump performance. The affinity laws state the following:

- Flow is proportional to shaft speed. Q1/Q2 = (N1/N2)

- Head (pressure) is proportional to the square of shaft speed.

- Power is proportional to the cube of shaft speed.

The key formula for us is the last one, which means that if a pool motor runs at one-half speed, the power consumption (all else being equal) will be ½ * ½ * ½ or one-eighth the original amount of power consumed. For example, if the old pool pump motor drew 1,000 watts and we replaced it with a variable-speed motor, the consumer can expect to pay for 125 watts on their next power bill. Also, because it is the motor that uses the electricity, replacing it with a variable-speed model provides virtually the same energy savings as replacing the whole pump with a variable-speed unit.

Other benefits

A variable-speed pool pump replacement motor also is a benefit in other ways.

1. As one might expect, the initial cost of a motor is less than that of a complete pump. The same principle that applied in yesteryear’s pool market, where single-speed pool motors were priced less than single-speed powered pool pumps, applies to today’s variable-speed market. The difference in price between variable-speed replacement pumps and variable-speed-replacement motors can be as much as 40 percent.

2. Another key advantage of installing a variable-speed motor is that the pool’s hydraulics do not need to be changed. This is often a hidden cost involved when replacing the old single-speed pump with a variable-speed pump. Many consumers simply do not need a 2- or 3-horsepower pump. By replacing the motor only with a variable-speed replacement motor, the consumer’s pump performance remains properly sized, so no plumbing work is required.

Often, the only way to incorporate an oversized pump into an existing hydraulic system is to enlarge the plumbing diameter — for example, changing the piping from 2-inch to 3-inch diameter. Because the installer can only perform this conversion on the visible piping, the piping under the ground or concrete remains undersized, which negates a significant portion of the perceived energy savings. By replacing only the current motor with a variable-speed replacement motor, the energy savings remain intact.

3. In many cases, a given pump is working fine, or the consumer is happy with its performance. So why replace the entire unit? Simply bring it to the latest in energy saving technology by swapping the old motor for a variable-speed replacement one.

4. Replacing the old single-speed motor with a new variable-speed replacement motor can also make the consumer’s pool pump run more quietly. The difference is comparable to that between a box fan when running at full speed vs. that same box fan running at half speed. The consumer will notice this difference very quickly, especially if their equipment pad is near the pool, patio or deck.

5. These variable-speed pool pump replacement motors are generally totally enclosed fan cooled or TEFC. TEFC motors, along with the integrated VFDs, are enclosed so the weather elements cannot easily affect the life of the internal electronics. Thus, these motors will generally last significantly longer than traditional pool motors.

These are many of the reasons why it pays to replace an old single-speed pool pump motor with a variable-speed motor. Improvements in energy-efficient motors in the pool market represent a significant untapped reserve of potential energy savings. The programmable VFDs also can save maintenance on consumers’ hydraulic systems because the program schedule needs to be set only once.

Reducing the motor speed or output also can cause less stress and lower operating temperatures on other system components, resulting in longer equipment life and better filtration. In addition to all these benefits, fewer plumbing complications, reduced running noise, and longer life make these products an excellent aftermarket pool motor choice.