Tile discoloration has plagued the pool industry for decades.

Most discoloration issues involve glass tile, more specifically translucent and transparent glass. This includes back-coated glass, which is essentially clear tile on five sides with a colored coating applied to the back. It is theoretically much safer from the effects of discoloration — unless, of course, the coating comes under attack, or discoloration within the installation system underneath is magnified through the clear sides of the glass, then transposed and viewed through the surface.

Tile discoloration can occur from a multitude of conditions occurring under the tile, including varying shades of thinset, microbial growth, trowel marks and/or voids in the thinset, degradation of back coatings, and the effects of mesh or glue on the back of the tile. These are five of the more common causes. And while mesh-backed glass should not even be considered on translucent glass, sadly it is still used in some instances.

Properly addressing the entire spectrum of reasons for discoloration would read like a postgraduate Masters dissertation, so for the purpose of this article, we’re going to lightly address two very different scenarios: discoloration of thinset under translucent glass (an installation issue); and degradation of back coated glass (a manufacturers issue).

Thinset shading: Arguably one of the most common causes of translucent tile discoloration has nothing to do with the tile and everything to do with the adhesive underneath; namely, thinset in most cases. Regardless of how beautiful an installation may turn out, if it develops blotchy areas or “racing stripes,” it’s a matter of living with it or tearing it out, with the latter generally overruling the former. This is an extremely costly mistake.

The first rule of thumb in avoiding discoloration includes using a color-consistent thinset. It must not only come from the same manufacturer, but must be made at the same plant, on the same day, and have a guarantee to be color consistent. For the best results, it should be designed for glass tile. Other important precautions: Use clean, potable water; mix in small, controllable batches; install in a controlled environment; achieve full contact with the thinset; and allow the installation to fully cure.

Degradation of back-coated glass: Most are familiar with back-coated glass, but for those who aren’t, think of a 1-by-1-by-3/8-inch-thick piece of absolutely clear glass. Now think about applying a coating to the back of it to create the color. As viewed from the front, what you see is a beautifully colored glass with incredible depth.

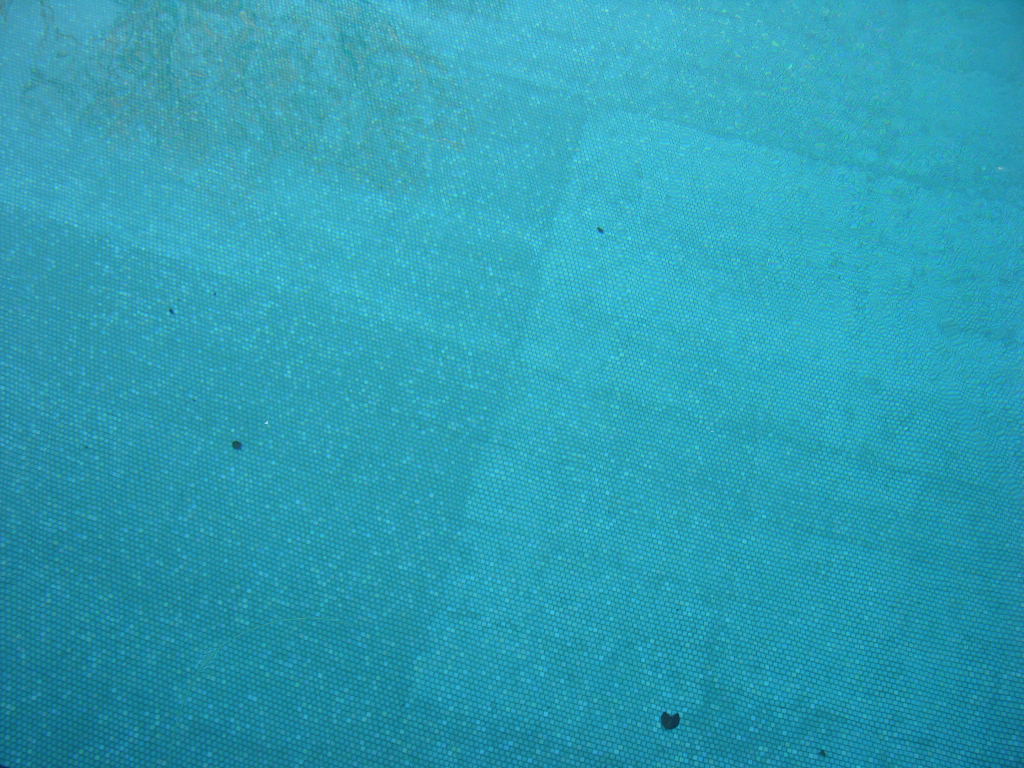

Once installed and put into service, unstable coatings can succumb to a variety of conditions such as ultraviolet rays, alkalinity from thinset and grouts or, as shown in the photo, pool water.

To perform in submerged conditions, the coating must be made of quality raw materials, high temperature fused, and verified to perform while submerged in chemically treated water.

Fortunately, these coatings don’t degrade too often, as most reputable manufacturers understand the consequences of unsuitable materials in submerged conditions. Sadly though, specifiers and/or end users are at times so taken by the beauty of a material that they ignore warnings and choose form over function, going with a tile that’s not made for the application.

Both the tile and pool industry have made great strides over the years in addressing issues such as discoloration. But then again, history is constantly repeating itself, and issues in the pool industry are by far no exception.

Greg Andrews is co-founder of National Tile and Stone Authority, a company that lends consulting, education and expert witness services related to tile and stone installation. A 42-year veteran tile installer, he is recognized as one the country’s premier experts in tile installation, with a specialty in glass mosaic. You can attend his presentation, The Five Most Common Pool Tile Issues and How to Avoid Them, at the virtual PSP Expo. Register at poolspapatio.com